IRONWORKERS IN STOCK TODAY

PIRANHA IRONWORKERS: BUILT FOR EVERY INDUSTRY'S TOUGHEST JOBS

@2025 Piranha / All rights reserved

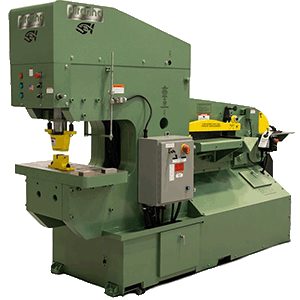

BII SERIES HYDRAULIC IRONWORKER MACHINES

Every Piranha ironworker machine delivers what you need most – reliability, durability, and repeatability starting at $25,900.

The BII Series is a complete Dual Operator Machine, utilizing two motors, pumps, and valve bodies to enable the operator to run the punching and shearing/notching sections entirely independently of each other.

GET A FREE QUOTE TODAY

Ready to increase your shop's productivity? Fill out this contact form and an Ironworker Specialist will help you select the best ironworker machine for your business.

Ship Today, Work Tomorrow

Starting at $18,995

The BII Series is a complete Dual Operator Machine, utilizing two motors, pumps and valve bodies to enable the operator to run the punching and shearing/notching sections entirely independently of each other. These machines are available in capacities from 66 to 225 Tons and come equipped with standard features as follows:

- Automatic Hydraulic Clamping in the Flat and Angle Shear Section

- Magnetic Work Light

- Productivity Package for the punching, shearing and notching stations.

1972

Bob Brown and Harry Osward first designed the P-50 Piranha Ironworkers.

From the dependable P-Series to the innovative BII-Series, Piranha delivers unmatched performance.

BII IRONWORKER MODELS

1995

P-II 140 - the largest domestically manufactured dual operator machine - was introduced.

Present

10,000+ P-50 ironworker models sold.

STRENGTH THAT STANDS THE TEST OF TIME

Piranha Ironworkers were first designed by two gentlemen, Bob Brown and Harry Oswald, in 1972. Piranha has been manufacturing in Hutchinson, KS, since that time. The Piranha is known for its unique design, features, manufacturing quality, and safety.

Since 1972 Mega Manufacturing has developed a full line of ironworkers for the steel working industry. The first Piranha designed was the P50. In 1986 the addition of the Dual Slide model was put into production and in 1986 Mega added the Single End Punch Press model. In 1995 Mega introduced the PII 140, the largest domestically manufactured dual operator ironworker.

BII SERIES PREMIER FEATURES

Our ironworker machines offer standard features unavailable elsewhere in the industry, including:

- Urethane stripper attachment*

- Automatic urethane hold-downs*

- Direct line of sight over the hold-down bar

- Low rake angle on flat bar shear

- Floating upper blade on angle shear

- Low rake angle on coper notcher

- Quick change tooling, via Piranha’s unique dovetail design*

*Available on most models

IRONWORKER MODELS

BII-132

132 Ton Dual Operator

BII-225

225 Ton Dual Operator

BII-88

88 Ton Dual Operator

PEOPLE LOVE THEIR PIRANHAS

PIRANHA IN ACTION

Piranha P-65 Ironworker on Motorhead Garage

Piranha Ironworker Machine Build and Testing Process

Shorts

Piranha Ironworker Tool Tip: Quick Set Attachment

Piranha Ironworker Tool Tip: Bending Attachment

Piranha Ironworker Tool Tip: Urethane Strippers

Piranha Ironworker Tool Tip: Back Gauge

1975

P-50 (serial number 050) was produced.

1994

5,000th P-50 model was sold.

Punch Gauging Table

The Punch Gauging Table offers an easy-to-use platform for aligning and punching materials with exceptional accuracy. Built for durability and precision, it enhances workflow and minimizes errors.

Coper Table Gauging

Achieve precise, repeatable cuts with the Coper Table Gauging system. Designed for accuracy and efficiency, this feature simplifies the alignment process, ensuring consistent results on every project.

Automatic Hydraulic Clamping

Effortlessly secure materials with precision using the Automatic Hydraulic Clamping system. This feature minimizes setup time and ensures a firm hold, enhancing productivity and safety for every task.

1986

The Dual Slide model was put into production.

Restored model shown left.

Restored model shown above.

1989

Single End Punch Press model was developed.

1996

Began manufacturing press brakes and shears.

BII-66

66 Ton Dual Operator

Dual Hydraulic System Allows for Independent or Simultaneous Operation

Boost productivity with the Dual Hydraulic System, enabling independent or simultaneous operation of the machine’s components. This innovative system maximizes efficiency for complex tasks and reduces downtime.

Bending Attachment

Expand your capabilities with the versatile Bending Attachment. Ideal for creating accurate bends in various materials, this accessory integrates seamlessly into the ironworker for optimal performance.

Electric Back Gauge

Streamline your operations with the Electric Back Gauge, a highly adjustable feature that provides precise material positioning for cutting and punching tasks. It’s designed to save time and improve accuracy.

Dual Hydraulic System Allows for Independent or Simultaneous Operation

Boost productivity with the Dual Hydraulic System, enabling independent or simultaneous operation of the machine’s components. This innovative system maximizes efficiency for complex tasks and reduces downtime.

| Model | Punch Tonnage | Plate Shear | Angle Shear | Notcher | Weight |

|---|---|---|---|---|---|

| BII-66 | 66 | 15-3/4″ x 5/16″ 9-1/2″ x 5/8″ |

4.5″ x 4.5″ x 7/16″ | 2-1/4″ x 3-7/8″ x 3/8″ | 4,400 lbs |

| BII-88 | 88 | 18-1/2″ x 3/8″ 13″ x 3/4″ |

5.5″ x 5.5″ x 7/16″ | 2-1/4″ x 3-7/8″ x 1/2″ | 5,950 lbs |

| BII-132 | 132 | 18-1/2″ x 3/8″ 13″ x 1″ |

6-1/4″ x 6-1/4″ x 5/8″ | 2-1/4″ x 3-7/8″ x 9/16″ | 10,800 lbs |

| BII-225 | 225 | 27-1/2″ x 9/16″ 15-3/4″ x 1-3/8″ |

7-3/4″ x 7-3/4″ x 11/16″ | 2-1/4″ x 3-7/8″ x 3/4″ | 16,975 lbs |

BII SERIES SPECIFICATIONS & CAPACITIES

Angle Mitre Attachment

The Angle Mitre Attachment is engineered for precision and versatility, allowing for clean and accurate angled cuts on a wide range of materials. Its robust design ensures stability, while easy adjustability simplifies the process of achieving perfect miters, making it an indispensable tool for detailed fabrication projects.

Get in touch with an Ironworker expert today.

Get in touch with an Ironworker expert today.

Get in touch with an Ironworker expert today.

Get in touch with an Ironworker expert today.

Get in touch with an Ironworker expert today.

Get in touch with an Ironworker expert today.

Highest value Dual-Operator on the market

In Stock and Ready to Work

The P Series ironworker machines offer standard features unavailable elsewhere in the industry, including:

- Urethane stripper attachment*

- Automatic urethane hold-downs*

- Direct line of sight over the hold-down bar

- Low rake angle on flat bar shear

- Floating upper blade on angle shear

- Low rake angle on coper notcher

- Quick change tooling, via Piranha’s unique dovetail design*

*Available on most models

P SERIES IRONWORKER MODELS

P-50

50 Ton Ironworker

P-65

65 Ton Ironworker

P-90

90 Ton Ironworker

P-110

110 Ton Ironworker

P-140

140 Ton Ironworker

PII-88

88 Ton Dual Operator

PII-140

140 Ton Dual Operator

INDUSTRY LEADING IRONWORKER

P SERIES FEATURES

Quick Change Tooling

Quick Change Tooling allows for fast and easy tool swaps, reducing downtime and enhancing productivity by keeping your workflow smooth and efficient.

Low Rake Angle

The Low Rake Angle on Piranha ironworkers delivers smoother, more efficient cuts with less distortion and strain, ensuring cleaner edges and precise results.

Auto Urethane Hold Down

The Auto Urethane Hold Down ensures a secure grip on materials during cutting and punching, automatically adjusting to material thickness for consistent, clean cuts with minimal movement.

Get in touch with an Ironworker expert today.

| Feature | P-Series | BII-Series |

|---|---|---|

| Operation | Single-operator models; dual-operator versions available. | Dual-operator machines with independent hydraulic systems. |

| Tonnage Capacity | 50 to 140 tons. | 66 to 225 tons. |

| Standard Features |

- Urethane stripper - Automatic hold-downs - Quick-change tooling. |

- Hydraulic clamping - Magnetic work light - Productivity package. |

| Punching Capacity | Up to 140 tons. | Up to 225 tons. |

| Shearing Capacity | Flat bars up to 18" wide (varies by model). | Flat bars up to 27-1/2" x 9/16". |

| Notching Capacity | Standard coper/notcher on models like P-90. | Advanced notching with productivity enhancements. |

| Additional Attachments | Optional: bending, pipe notching, gauging tables. | Standard: punch gauging, bending, electric back gauges. |

| Design Focus | Versatile, compact; single/dual operation options. | High productivity; dual-operation for large-scale needs. |

COMPARE

P SERIES HYDRAULIC IRONWORKER MACHINES

Every Piranha ironworker machine delivers what you need most – reliability, durability, and repeatability starting at $17,995.

Backed by the Piranha reputation for quality and innovation, our hydraulic ironworker machine lines range from 50 to 140 tons, with both single-operator machines and dual-operator machines available.

In Stock and Ready to Work

Get in touch with an Ironworker expert today.

| Feature | P-50 | P-65 | P-90 | P-110 | P-140 |

|---|---|---|---|---|---|

| Punching Capacity | 50 tons; 13/16" through 3/4" | 65 tons; 1-1/16" through 3/4" | 90 tons; 1-1/8" through 1" | 110 tons; 1-7/16" through 1" | 140 tons; 1-3/4" through 1" |

| Throat Depth | 8" | 8" | 10" | 12" | 12" |

| Flat Bar Shear | 3/4" x 6" | 3/4" x 6" | 1" x 8" | 1" x 12" | 1" x 14" |

| Angle Shear | 5" x 5" x 3/8" | 3.5" x 3.5" x 5/16" | 5" x 5" x 1/2" | 5" x 5" x 1/2" | 6" x 6" x 5/8" |

| Round Bar Shear | 1/4" to 1.5" | Optional | 1/2" to 2" | 1/2" to 2" | 1/2" to 2" |

| Square Bar Shear | 1/2" to 1" | Optional | 1/2" to 1-3/8" | 1/2" to 1-3/8" | 1/2" to 1-3/8" |

| Coper Notcher | 2.75" x 4" | 2.25" x 3" | 3.5" x 5" | 4" x 6" | 4" x 6" |

| Stroke Length | 4.25" | 3.75" | 4.875" | 5.25" | 5.25" |

| Motor Power | 3 HP | 7.5 HP | 10 HP | 10 HP | 15 HP |

| Weight | 1,700 lbs | 2,600 lbs | 4,250 lbs | 5,800 lbs | 6,200 lbs |

P SERIES SPECIFICATIONS & CAPACITIES