Piranha Handheld LASER Welders

Piranha Handheld LASER Welders

LASER WELDING BENEFITS

Effortless Operation, Seamless Welding, Superior Results!

Compared to traditional welding methods, Piranha’s MA1 series of handheld LASER welding machines significantly boosts welding speed (four times faster for mild steel). They are easy to learn and operate, save energy, and are eco-friendly.

LASER Welder Models include:

- MA1-65: Maximum Power – 1.5kW

- MA1-45: Power with Portability 1.2kW

- MA1-35: Excellent Portability 1kW

See our model specifications to learn which one best meets your welding needs.

Learn More

About This Piranha Product

These LASER welder machines are easy to operate across a wide range of materials, including stainless steel, carbon steel, aluminum, galvanized steel, and copper. Our LASER welders deliver four times faster welding speeds, higher weld strength, and reduced porosity.

The MA1 series minimizes heat-affected zones, eliminating weld deformation and burn-through. This results in a cleaner weld that requires little to no postprocessing, such as grinding or polishing.

The MA1 series enhances efficiency and productivity, reduces waste, and lowers costs, effectively boosting your profitability.

Download a LASER Welder Brochure

Model Specifications

| LASER Welder Model | MA1-65 | MA1-45 | MA1-35 | |

| Weld Thickness* | Stainless | 1/4″ / 6.5mm | 0.18″ / 4.5mm | 0.14″ / 3.5mm |

| Carbon Steel/Iron | 1/4″ / 6.5mm | 0.18″ / 4.5mm | 0.14″ / 3.5mm | |

| Aluminum | 0.22″ / 5.5mm | 0.16″ / 4mm | 1/8″ / 3mm | |

| Galvanized sheet | 1/4″ / 6.5mm | 0.18″ / 4.5mm | 0.14″ / 3.5mm | |

| Copper | 0.12″ / 3mm | 1/16″ / 1.5mm | – | |

| Wobble | 0-0.16″ / 0-4mm | 0-0.16″ / 0-4mm | 0-0.16″ / 0-4mm | |

| Operating Temperature | 0~104F / 0~40C | 0~104F / 0~40C | 0~104F / 0~40C | |

| Weight | 86 lbs / 39 kg | 84 lbs / 38 kg | 62 lbs / 28 kg | |

| Dimensions | 26.3 x 10.9 x 21.3 in

667 x 276 x 542 mm |

26.3 x 10.9 x 21.3 in

667 x 276 x 542 mm |

22.7 x 10.4 x 16.7 in

576 x 265 x 425 mm |

|

| Volume | < 3.5 cu ft

< 0.1 m2 |

< 3.5 cu ft

< 0.1 m2 |

2.1 cuft

0.06 m2 |

|

* Remarks: The data is extreme penetration depth based on lab test results; the penetration depth performance will vary according to different setups and applications.

LASER WELDING BENEFITS

Compared to traditional welding methods, Piranha’s MA1 series of handheld LASER welding machines significantly boosts welding speed (four times faster for mild steel). They are easy to learn and operate, comply with European safety standards, save energy, and are eco-friendly.

Piranha’s MA1 series features a high-precision LASER control system, stable beam quality, and LASER powers ranging from 1,000 to 1,500 watts. Even novices can effortlessly achieve weld depths from 1.5mm to 6.5mm with little to no welding wire consumption, ensuring high-quality, strong welds every time!

INCLUDES WIRE FEEDER UNIT – INTEGRATED WOBBLE WELDING

The LASER control system ensures consistent wobble frequency control, allowing for weld widths of up to 4.0mm (approximately 0.16″). This results in high-quality, symmetrical weld seams that are smooth to the touch and require no further processing.

The MA1 series includes a wire feeder module for instances where deeper weld penetration is necessary, such as filling gaps or achieving smooth, flush weld profiles. The module supports welding wire diameters of 1.0mm (approximately 1/25”), 1.2mm (approximately 3/64”), and 1.6mm (approximately 1/16”). It is compatible with a variety of materials, including carbon steel, stainless steel, aluminum, non-ferrous metals, and other alloys.

PIRANHA HANDHELD LASER WELDER FEATURES

- STABLE PERFORMANCE AND RELIABLE QUALITY

Piranha’s new MA1 series handheld laser welder is engineered with Maxphotonics’ world-class laser technology, ensuring precise

LASER control and stable beam quality. Each unit undergoes rigorous testing before leaving the factory, including a 500-hour high and low temperature (-10°–45° or -14°–113°) cycling power test and a 12-hour continuous welding test with 99% power stability. With a LASER power source lifespan of approximately 100,000 hours, all our products meet SGS industry standards to guarantee stable and durable beam output. - COMPACT HANDHELD WELDING TORCH

Equipped with a collimated QCS interface, our welding torch is impressively lightweight at just 680g (1.5 pounds). Its optical design and QCS output head are seamlessly integrated, providing high transmission efficiency and heat output. Ergonomically crafted for user comfort, the torch is easy to operate. We’ve also included a built-in wobble function with a double safety laser on button, allowing operators to work safely all day while consistently delivering high-quality welds. - COMPACT AND MOBILE

Piranha’s new generation of handheld LASER welders is engineered for portability, making it ideal for mobile welding projects. With options ranging from 28kg to 39kg (62-86 pounds), you can choose the product that best suits your welding needs and performance criteria. The compact design, occupying less than 0.1m³ (3.5 cubic feet), enhances its portability, allowing for easy transport and set up. - SIMPLE OPERATING SYSTEM, INTELLIGENT PROCESSING MODE

Piranha’s new MA1 generation of handheld LASER welding products features a 7″ LED touchscreen and an intelligent, multi-language operating system. With simple operation modes, it’s easy to learn and quick to operate. Even beginners can master the welding operation with just 1-2 hours of training, significantly reducing both training and production costs.The device comes pre-loaded with 32 sets of process parameters and allows for user customization. This enables operators to swiftly select welding parameters based on various materials and thicknesses, allowing even novice welders to produce welds of the same high quality and consistency as experienced welders. - EASY INSTALLATION AND OPERATION

The product’s rear panel is clearly labeled for effortless set up, making it especially convenient for beginners. Installation is further simplified with our user guide videos. All you need is a standard 220Vac power plug, a connection to industrial shielding gas like argon or nitrogen, and a ground clamp attached to your workpiece to start using the equipment. The 7-inch LED touchscreen features an intelligent, multi-language operating system. Here, you can easily select from preset welding parameters or input your own user-defined settings. - LIGHTWEIGHT, PORTABLE, AND ENGINEERED FOR HIGH PERFORMANCE

With traditional welding methods, it is difficult to teach complex welding processes, efficiency is low, and critically, the weld quality depends to a greater extent on the welder’s experience only. The new generation of Piranha’s MA1 handheld laser welding products brings with it high welding efficiency, simple and convenient operation, and easy-to-learn technology. Anybody can be trained to achieve consistent, high-quality welding results in a range of different materials and thicknesses very quickly.

Goodbye to Traditional Welding!

Highly trained welders, technically complex welding processes, poor work environments, low efficiency, unsuitability for special metals and thin sheets, high welding wire consumption, and the need for precleaning and joint preparation grooves for full penetration. Vertical welding is notably challenging due to limited direction and operating angles.

- HEAT-AFFECTED ZONE: Traditional welding often distorts and discolors the workpiece due to heat, affecting weld quality by introducing porosity, reducing joint strength, altering grain structure, and necessitating further postprocessing. Welding materials like copper and aluminum also face thickness limitations.

- HEALTH AND SAFETY RISKS: The arc’s ultraviolet and infrared radiation can harm the welder’s eyes and skin. Additionally, inhalation of fumes at the weld site is a concern, often requiring strong extractors.

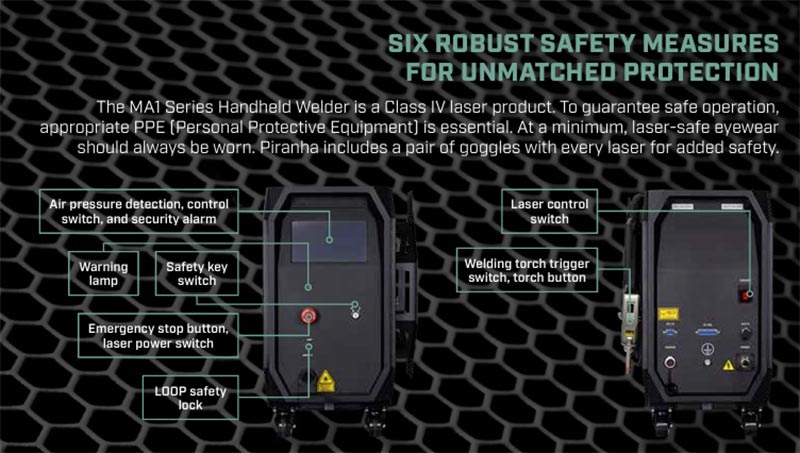

SAFETY

The MA1 Series Handheld Welder is a Class IV laser product. To guarantee safe operation, appropriate PPE (Personal Protective Equipment) is essential. At a minimum, laser-safe eyewear should always be worn. Piranha includes a pair of goggles with every laser for added safety.

BUDGETARY PROPOSAL

This budgetary proposal is a reference document and subject to change without notice. Upon request, a final proposal will be issued including firm pricing and contractual information. This budgetary proposal is not an agreement on pricing or specifications.

Additional information

| Weight | 86 lbs |

|---|---|

| Dimensions | 26.3 × 10.9 × 21.3 in |