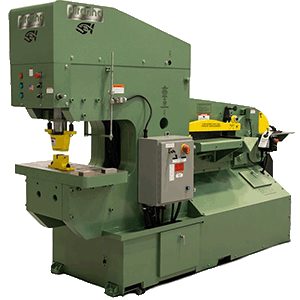

Hydraulic Ironworker Machine

Every Piranha ironworker machine delivers what you need most –

reliability, durability, and repeatability starting at $15,995

Backed by the Piranha reputation for quality and innovation, our hydraulic ironworker machine lines range from 50 to 140 tons, with both single-operator machines and dual-operator machines available.

Thanks to a wide range of ironworker machine tooling and ironworker machine attachments, a Piranha ironworker machine offers unparalleled versatility, as well as savings in machine set-up time.

P-50

50 Ton Ironworker

Starting at $15,995

Spec + Buy Now!

P-65

65 Ton Ironworker

Starting at $27,995

Spec + Buy Now!

P-90

90 Ton Ironworker

Starting at $37,995

Spec + Buy Now!

P-110

110 Ton Ironworker

Starting at $43,995

Spec + Buy Now!

P-140

140 Ton Ironworker

Starting at $49,995

Spec + Buy Now!

PII-88

88 Ton Dual Operator

Starting at $53,995

Spec + Buy Now!

PII-140

140 Ton Dual Operator

Starting at $88,995

Spec + Buy Now!

Begin building your perfect Piranha Shop today!

Valuable Features

Our ironworker machines offer standard features unavailable elsewhere in the industry, including:

- Urethane stripper attachment*

- Automatic urethane hold-downs*

- Direct line of sight over the hold-down bar

- Low rake angle on flat bar shear

- Floating upper blade on angle shear

- Low rake angle on coper notcher

- Quick change tooling, via Piranha’s unique dovetail design*

*Available on most models

Ergonomic Design That Delivers

Piranha ironworker machine workstations are at a consistent, ergonomic level across the machine, making our ironworker machines easily adaptable to material feed systems without having to adjust the feed system height between stations.

The Complete Package

Durability. Versatility. Dependability.

Combine all of that with Piranha’s superior factory engineering and support, and you have a hydraulic ironworker machine that delivers the performance your operation demands.

Fabrication Equipment

Thermal Cutting Machines

Contact Piranha

- 650 Race St.

Rockford IL 61105, USA - Toll Free: 800-338-5471

- Local: 815-964-6771