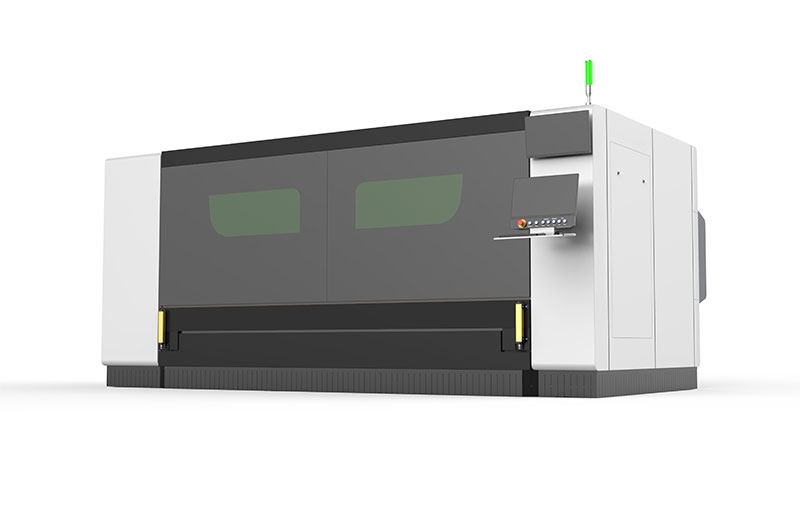

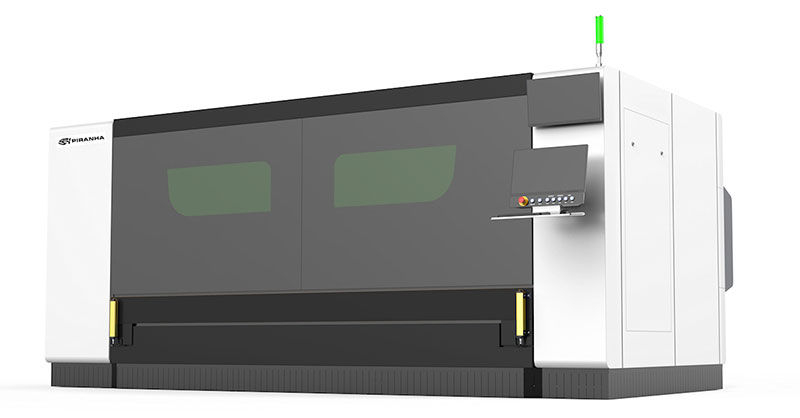

SP510 Fiber LASER

SP510 Fiber LASER

SP510 Fiber LASER System Includes:

- Single Pallet for Reduced Floor Space

- 60″ X 120.25″ cutting area

- 3.0kW fiber resonator

- Chiller

- Helical rack and pinion positioning system

- 3,150 IPM (80 m/min) maximum travel rate per axis

- Windows 10 CNC control with Cypcut

- Red diode LASER pointer

- Automatic Lubrication System with timer

- Automatic Cutting Gas Control and proportional valve

- Segmented Downdraft Dust Removal System with Blower

- See Full Product Description

Additional Options:

Learn More

About This Piranha Product

Piranha fiber LASER metal cutting machines are built with reliability and economy in mind. These tough machines use proven technology to ensure precision and reliability throughout their service life. This special combination of durability and cost efficiency provides maximum value for steel processors.

SYSTEM FEATURES

- 60″ X 120.25″ cutting area

- 3.0kW fiber resonator

- Chiller

- Helical rack and pinion positioning system

- 3,150 IPM (80 m/min) maximum travel rate per axis

- Windows 10 CNC control with Cypcut

- Red diode LASER pointer

- Automatic Lubrication System with timer

- Automatic Cutting Gas Control and proportional valve

CUTTING TABLE WITH FUME EXTRACTION SYSTEM

- Segmented Downdraft Dust Removal System with Blower

- Single Pull-Out Pallet for Reduced Floor Space

NOTE: Best performance is obtained by including the optional dust collector for steel or aluminum cutting.

FIBER LASER RESONATOR

- INCREASED efficiency

- REDUCED operating costs

- NO beam path optics or mirrors

- NO periodic service requirement

GRAPHICAL CNC CONTROL WITH CYPCUT

Piranha SP510 LASERs include a graphical CNC control with Cypcut software. It is a control system and software designed for sheet metal fabrication. Individual or multiple parts are imported as DXF files and can be nested automatically or manually. No knowledge of G- and M-codes is required.

Cypcut software is available as a free download and can be installed on any number of computers for offline programming at no additional cost. The completed nests can be directly transferred to the LASER CNC control via a network connection.

Features include:

- AI, DXF, PLT, Gerber, LXD file format, and standard G code import

- File optimization including removal of duplicates, connecting unclosed segments, removing minimal graphics and distinguishing inner and outer contour and setting machining sequence automatically.

- Graphic edit functions including zooming, translation, mirror, rotation, alignment, replication, and combination.

- Application of lead lines, cut seam compensation, micro-joint, bridge, inner/outer cut, etc.

- Automatically distinguish inner and outer contour then determine the compensation direction and checking of the lead line.

- Support curve split, merge and smooth; transfer text to curve; parts combination and explode etc.

- Automatic nesting including common line cutting and remnant nesting.

- Manual nesting by array function.

- Flexible sorting functions. Users can group the graphics to lock the cutting sequence.

- Preview the cutting sequence.

- Quick set fly cutting.

- Support of various piercing methods including segmented pierce, incremental pierce, pre-pierce, group pre-pierce. Users can also set separate parameters of pierce and cutting including LASER power, frequency, gas, pressure, peak power, delay, cut height etc.

- Powerful material library function allows all process parameters to be saved for reuse of the same material.

- Breakpoint memory when the cutting process is interrupted. Users can select resume position before or after breakpoint.

- Users can locate to specified position in stop or pause status and resume cutting.

- Supports round tube and plane sheet cutting.

- Supports intersecting line cutting.

- Supports various edge-find methods with high precision.

- Supports remote control of the system through wireless operator and ethernet.

Service, training, and support of the CNC control and Cypcut is provided by Piranha.

CAM PROGRAMMING AND NESTING SOFTWARE

CNC Programming of the Piranha SP510 requires CAM software capable of supporting the advanced functions of the machine. The Cypcut software is provided by Piranha and is the preferred system.

If another CAM software system is used, the customer is responsible for all costs associated with the development of any new post processor from their selected CAM software vendor. Piranha will provide any information required for the post processor development and will verify that the NC code samples created by that post processor are functional. Requests for information and NC code samples for testing must be received by Piranha eight (8) weeks prior to the scheduled machine shipment.

If extra start-up time is required by Piranha to work with the CAM provider and to test the NC code during or after the machine installation, the additional Piranha service time and expenses will be invoiced to the customer at Piranha’s standard service rates.

SPECIFICATIONS

| Machine Model | Piranha LASER SP510 |

| LASER Type | Fiber |

| LASER Power | 3 kW |

| Optional LASER Power | 6.0kW |

| Drive Type | X-Axis – Helical Rack and Pinion Y-Axis – Helical Rack and Pinion Z-Axis – Ballscrew |

| Metric | Imperial | |

| Max Working Area | 1550 x 3100 mm | 61 x 122 inch |

| Positioning speed – X axis | 80 m/min | 3,150 IPM |

| Positioning speed – Y axis | 80 m/min | 3,150 IPM |

| Positioning speed – Z axis | 60 m/min | 2,362 IPM |

| Accelerations – X and Y axis | 7.85 m/s2 | 0.8 g |

| Positioning Accuracy – X & Y | 0.03 +/- mm | 0.001 +/- inch |

| Repeatability | 0.3 +/- mm | 0.001 +/- inch |

| Max Cutting Speed | 80 m/min | 3150 IPM |

MAXIMUM SHEET THICKNESS*

3 kW Sheet Thickness

| Carbon steel | 19 | mm | 0.750 | Inch |

| Stainless steel /N2 | 9.5 | mm | 0.375 | Inch |

| Aluminum | 9.5 | mm | 0.375 | Inch |

6 kW Sheet Thickness

| Carbon steel | 25 | mm | 1.000 | Inch |

| Stainless steel /N2 | 25 | mm | 1.000 | Inch |

| Aluminum | 20 | mm | 0.750 | Inch |

*NOTE: When cutting at or near the maximum material thickness for each process, it may be necessary to compensate for variations in material chemistry, surface condition, and thickness deviation from lot to lot. Some situations may require the use of LASER-grade materials.

GAS REQUIREMENTS

| GAS | PURITY | CONSUMPTION |

| Oxygen (Mild Steel Cutting) |

99.95% | 40 ~ 350 scfh @ 140 PSI 19 ~ 165 L/min @ 9.5 Bar |

| Nitrogen (Stainless, Aluminum Cutting) |

99.8% | 320 ~ 3000 scfh @ 300 PSI 150 ~ 1400 L/min @ 20 Bar |

NOTE: Customer shall install and utilize bulk liquid and bulk liquid nitrogen storage tanks. Using portable tanks for O2 or N2 will create additional chances of contamination entering the gas supply lines and the cutting head due to frequent tank changes. Contamination will cause cutting head lens failure and thus cause machine down time and additional operating expense.

POWER REQUIREMENTS

| ITEM | VOLTAGE | CURRENT |

| Machine, Resonator (2kW, 3kW), Chiller | 480/3/60 VAC | 65A |

| Dust Collector | 480/3/60 VAC | 25A |

NOTE: Transformers are available for other voltages. Contact Piranha for more information.

AMBIENT CONDITIONS

The Piranha SP510 must be located in an area which has the following ambient conditions:

- Ambient temperature between 10° and 40°C [50° and 104°F]

- Relative Humidity at 95% or less

OPTIONS

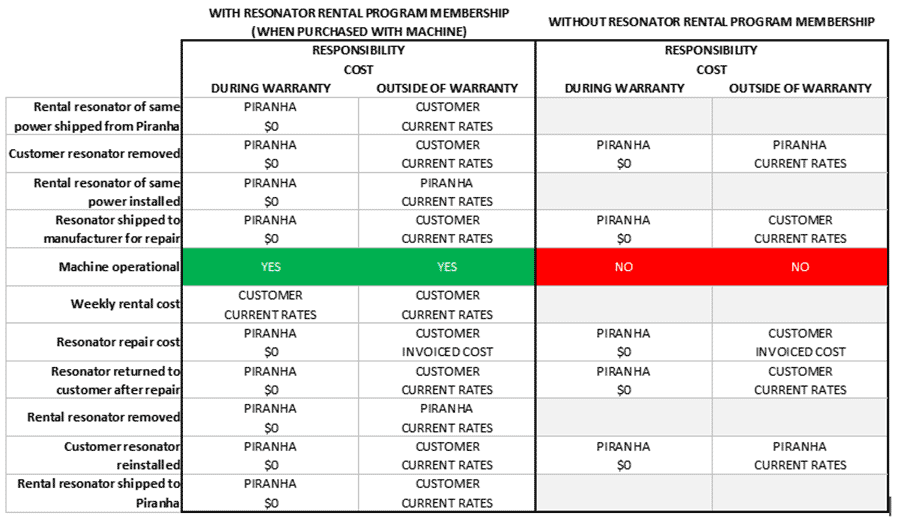

RESONATOR RENTAL PROGRAM

Piranha SP510 lasers include rack mounted resonators. In the rare instance where repair is required, the resonator will be removed from the laser and shipped to the resonator manufacturer for repair. The Piranha SP510 laser will be inoperable during that period. The RESONATOR RENTAL PROGRAM is designed to provide a loaner resonator in those instances.

Fiber LASER Resonator Rental Program Description

CONSUMABLE KITS

Consumable kits are available which provide a starting stock of items that are recommended for a range of LASER cutting applications.

LAMINAR FLOW BOX

Piranha recommends an optics servicing area to be located away from manufacturing areas. This area must have minimum air movement and a dust free environment. For best results, we recommend purchase of a laminar flow box located in an office area.

NOTE: Optics contamination is the leading cause of premature cutting head failure. It is important that optics, such as cover slides, are changed in an extremely clean environment. This area will also be used for on-site cutting head maintenance (to be done by our technicians).

AIR CUTTING ASSIST GAS COMPRESSOR SYSTEMS

Oxygen (O2) and nitrogen (N2) are the most common assist gases used when cutting metals with a fiber LASER. Air is a combination of both O2 (21%) and N2 (78%), small amounts of argon and carbon dioxide, and trace amounts of other gases and water vapor.

Air cutting provides many of the benefits of N2 cutting along with increased cutting speeds in thicknesses 10ga (0.135″) and thinner and significantly lower cutting gas costs.

Air used in LASER cutting must be available with the correct purity, dryness, pressure, and flow. Typical shop air compressor systems are unable to deliver the air quality and performance necessary. A dedicated air compressor system is required.

SUPPORTS ONE MACHINE

| F30 | |

| Air Flow Rate | 1,800 SCFH |

| Delivery Pressure | 204 PSIG |

| Air Compressor | 20 HP |

| Components |

|

| Recommended For | SP510 E510 FLEX series PlateLASER series |

SUPPORTS TWO MACHINES

| F50 | |

| Air Flow Rate | 3,000 SCFH |

| Delivery Pressure | 204 PSIG |

| Air Compressor | 25 HP Ozen Compressor |

| Components |

|

| Recommended For | SP510 E510 FLEX series PlateLASER series |

| Options | Upgrade to Kaeser Compressor Annual Filter Maintenance Kit |

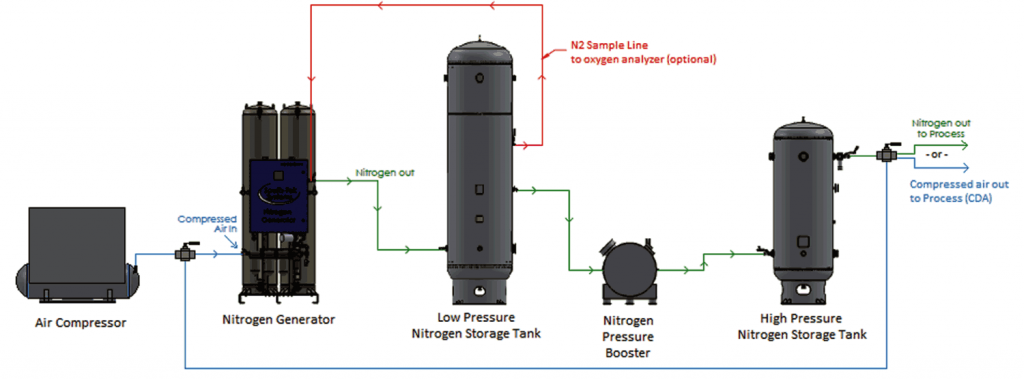

NITROGEN GENERATION SYSTEMS

Nitrogen generator is the separation of air components to capture nitrogen. Nitrogen makes up 78% of the gas in the atmosphere. The rest is 20.9% oxygen, 0.9% argon, 0.03% carbon dioxide and trace gases such as hydrogen, helium, neon, krypton, and xenon. For industrial laser cutting equipment, PRESSURE SWING ABSORPTION (PSA) is used to provide the high pressures and flow rates required.

NOTE: The maximum flow rate and purity required depend upon the cutting application and edge quality expectations. Other nitrogen generation systems are available to meet different requirements. Please contact Piranha for more information.

| F3000 | F4000 | F5000 | |

| N2 Flow Rate | 3,000 SCFH | 4,000 SCFH | 5,000 SCFH |

| Purity | 99.50% | 99.50% | 99.50% |

| Delivery Pressure | 400 PSIG | 400 PSIG | 400 PSIG |

| Air Compressor | 40 HP | 50 HP | 60 HP |

| Booster Compressor | 10 HP | 20 HP | 20 HP |

| Warranty | 3 years | ||

| Components |

|

||

| Recommended For |

|

|

|

DUST COLLECTION FOR LASER CUTTING EQUIPMENT

TODC-4L Dust Collector

The Piranha SP510 LASER comes with an integrated fume exhaust fan to remove dust from the enclosure during laser cutting.

A TopSinn 4-filter TODC-4L dust collector is available in lieu of the standard fume exhaust fan. The TODC‑4L features include:

- Integrated industrial made from high-quality cold-rolled steel plate with electrostatic paint finish

- American HV filter element with quick release design

- High-efficiency high-speed motor with built-in controller

- Low noise, high efficiency, low energy consumption

- No scheduled maintenance

- Dynamically balanced high-speed vortex fan

SPARK ARRESTING SYSTEM FOR CUTTING ALUMINUM

The TODC-4L dust collector (optional) is adequate for mild steel and stainless steel cutting. A spark arresting system can be installed between the laser and dust collector to enhance dust collection safety when cutting aluminum. The TODC-4L dust collector is required for this option.

Piranha suggests that you and your insurance provider review the pertinent NFPA standards prior to making any decision about aluminum dust collection and handling methods when cutting both aluminum and steel/stainless steel on the same machine. Pertinent NFPA standards include, but are not limited to, NFPA 484, NFPA 654 and NFPA 68

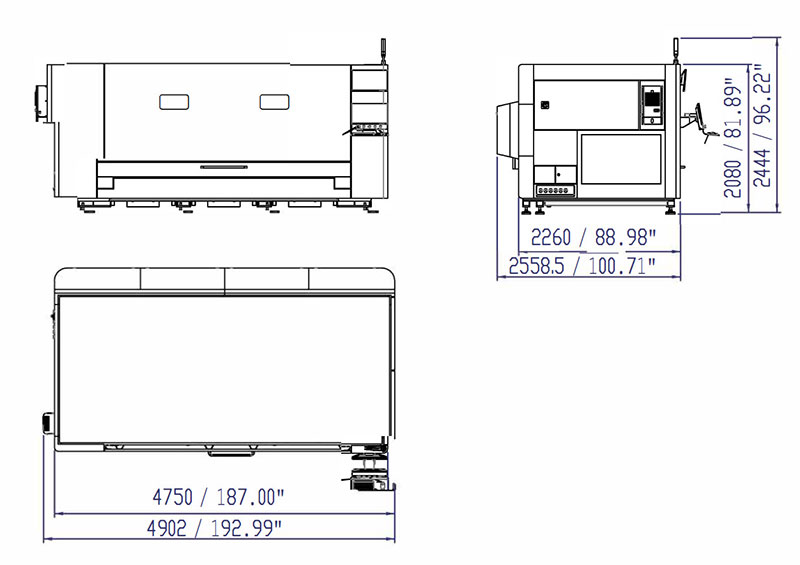

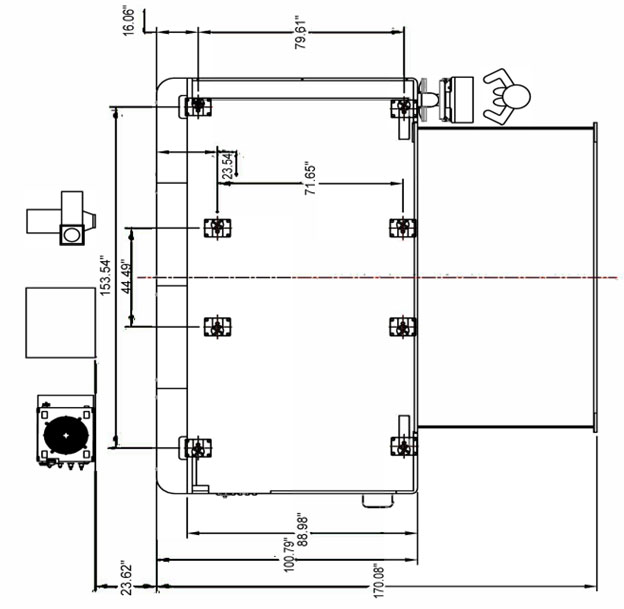

FLOOR SPACE & FOUNDATION REQUIREMENTS

No special foundation is needed for the Piranha laser. Standard concrete floors of a minimum 150mm (6”) depth are recommended. Flatness should be within 12mm (0.5”). There should be no expansion joints, saw cuts, or cracks in the floor beneath the frame of the laser.

BUDGETARY PROPOSAL

This budgetary proposal is a reference document and subject to change without notice. Upon request, a final proposal will be issued including firm pricing and contractual information. This budgetary proposal is not an agreement on pricing or specifications.