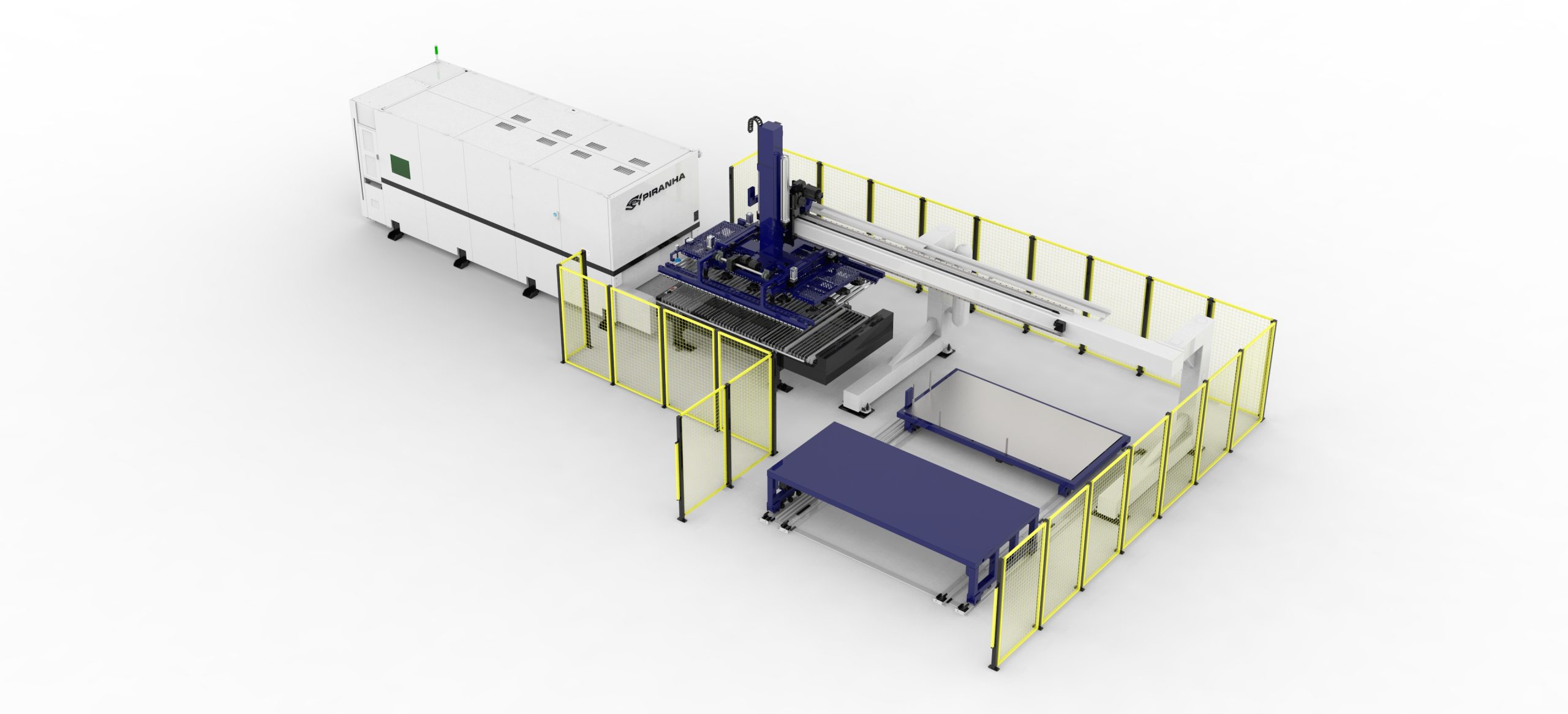

AG Series CNC Laser Automation System

AG Series CNC Laser Automation System

AG Series CNC Laser Automation – Load/Unload System

Automated sheet loading and unloading in a compact gantry system. Designed to reduce manual handling, cut idle time, and keep your Piranha fiber laser cutting more.

Request a custom AG Series automation quote.

Share a few details below and we’ll follow up with pricing and configuration options.

Learn More

About This Piranha Product

AG Series CNC Laser Automation – Load/Unload System

Fast, automated sheet loading and unloading in a compact, customizable gantry system.

Automate Your Material Flow

The AG Series CNC Laser Automation system streamlines material handling for your Piranha fiber laser. It automatically loads raw sheets and unloads finished parts, cutting down on manual lifting and reducing idle time between jobs.

You get faster changeovers, more consistent throughput, and a smoother workflow—without the footprint or investment of a full tower system. Each AG Series setup is fully customizable to match your shop layout and production needs.

Why Add Load/Unload Automation?

- Reduce manual material handling and operator fatigue

- Shorten changeovers between sheets and jobs

- Increase cutting time vs. handling time

- Improve workflow consistency and part flow

- Support higher productivity on a single shift—or multiple shifts

What the AG Series Delivers

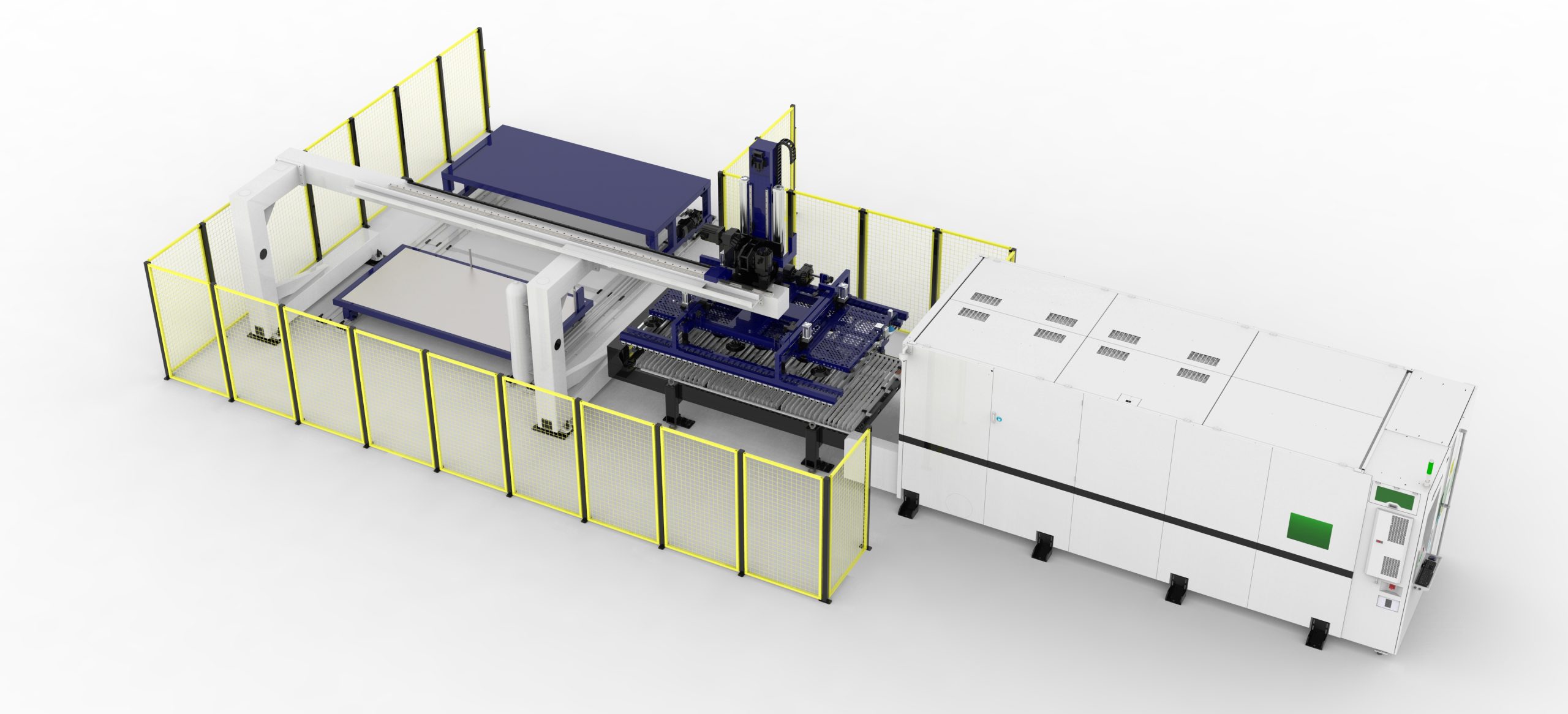

- Automated Loading and Unloading

- The AG Series handles the heavy lifting for you. Sheets are pulled from a staging area, loaded onto the cutting table, and finished sheets are moved to an unload position—all with minimal operator input.

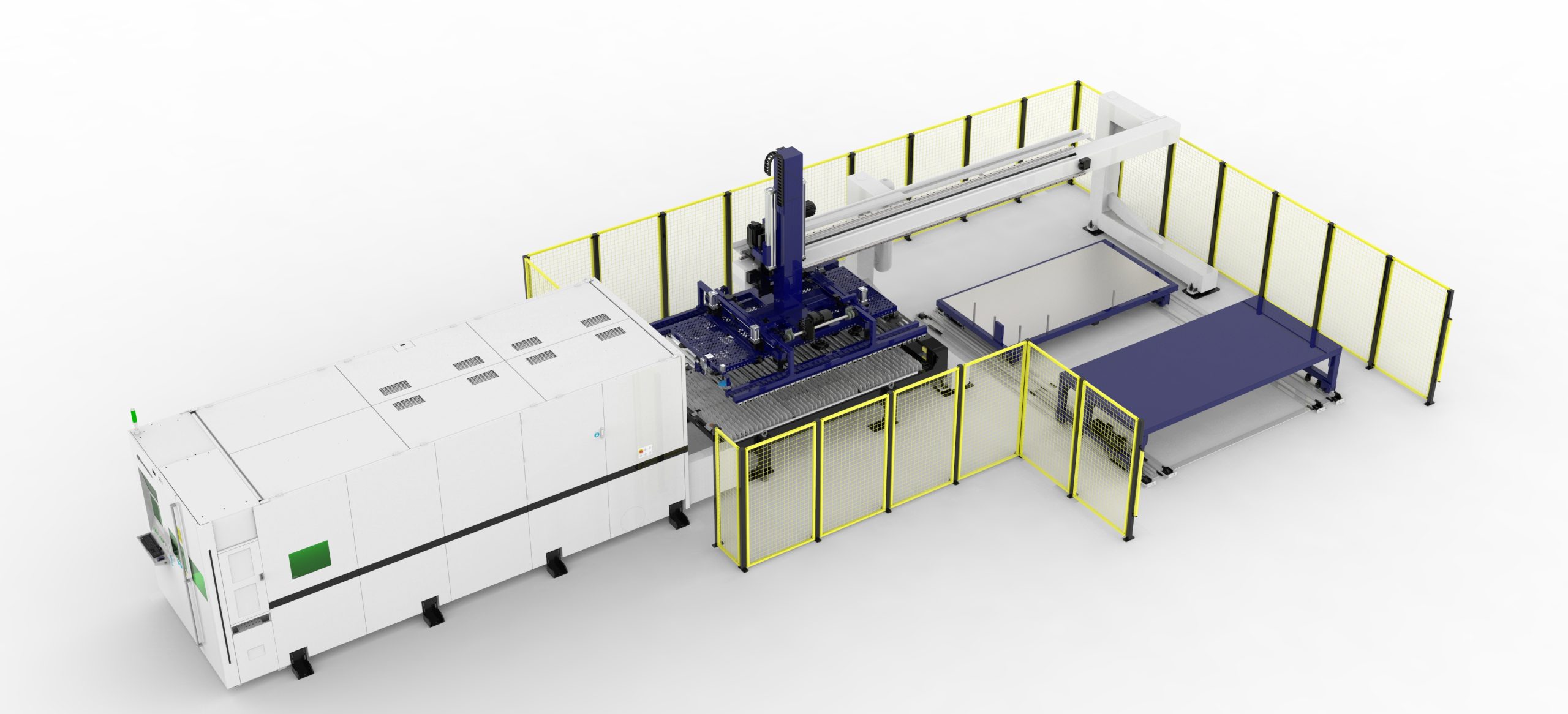

- Compact, Efficient Design

- You get the core benefits of automation in a smaller footprint, ideal for shops that stage material on the floor or don’t need vertical storage.

- Custom-Built for Your Shop

- Each system can be configured and oriented to fit your space, material flow, and production goals.

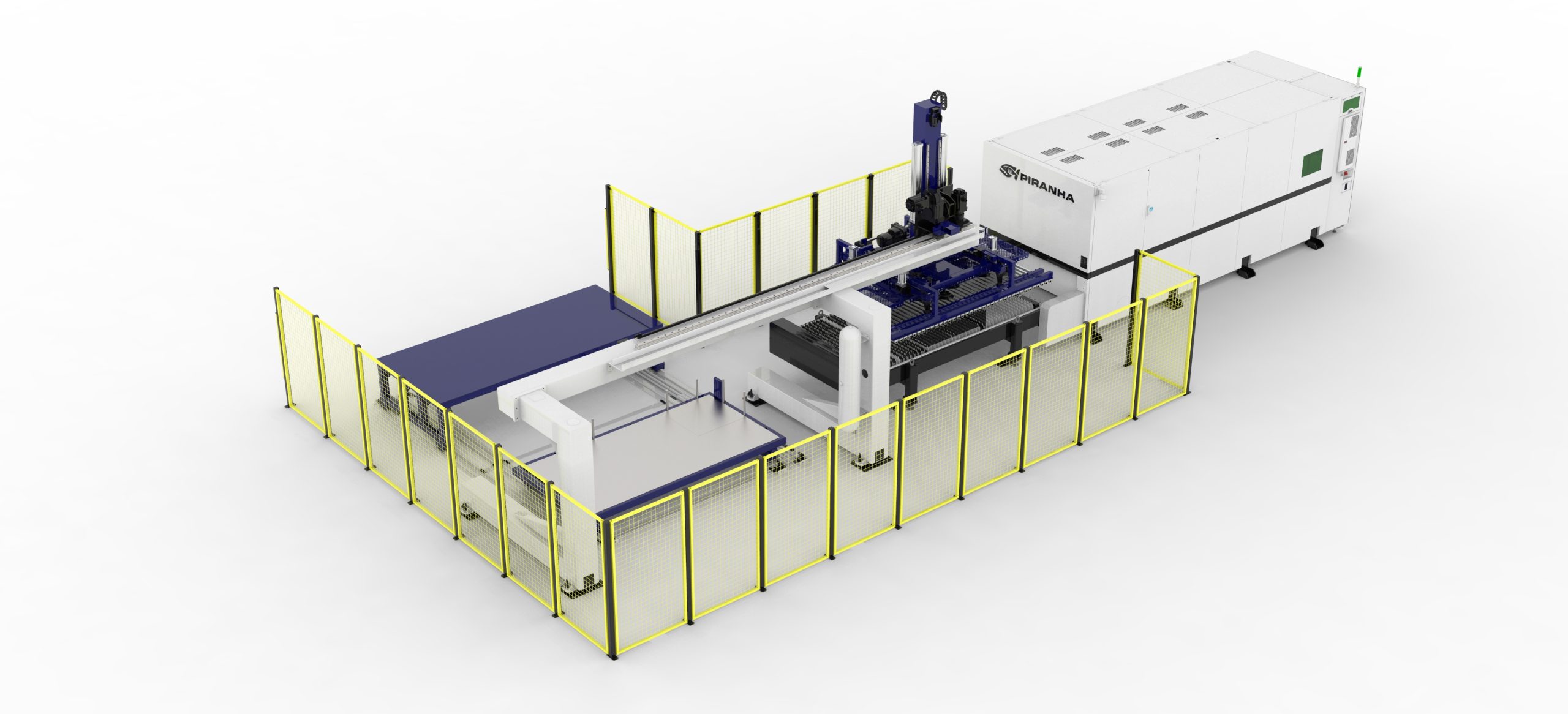

Custom Configuration Options

The AG Series can be tailored to how your shop works today—and how you plan to grow:

- Supported sheet sizes (4×4, 5×10, 6×12)

- Material staging and unload positions

- Flow direction (left, right, front, rear)

- Integration with surrounding equipment and walkways

- Safety guarding and access paths

Tell the team how you run material now, and the system can be configured around that.

Designed for Faster, More Consistent Production

- Faster Changeovers: Automated exchanges reduce the time between cuts.

- Better Use of Labor: Operators spend more time running the laser and less time moving sheet.

- More Predictable Output: Consistent loading/unloading cycles make production planning easier.

Ideal Applications

- Shops ready to move beyond fully manual loading

- Fabricators staging material on the floor or racks

- Small to mid-size operations growing into higher volume

- Multi-job, multi-material environments

General Specifications

(Values can be finalized based on your configuration.)

- System Type: CNC laser load/unload gantry

- Compatible Sheet Sizes: 4×4, 5×10, 6×12

- Max Sheet Weight: Typically 2,000–6,000 lbs (config-dependent)

- Material Flow: Customizable orientation

- Integration: Designed for Piranha CNC fiber lasers

Why Piranha CNC Fiber Lasers?

Ready to Build Your Automation System?

The AG Series can be engineered around your production goals, shop layout, and future growth.

Contact our team for pricing, layout assistance, and a custom configuration quote.