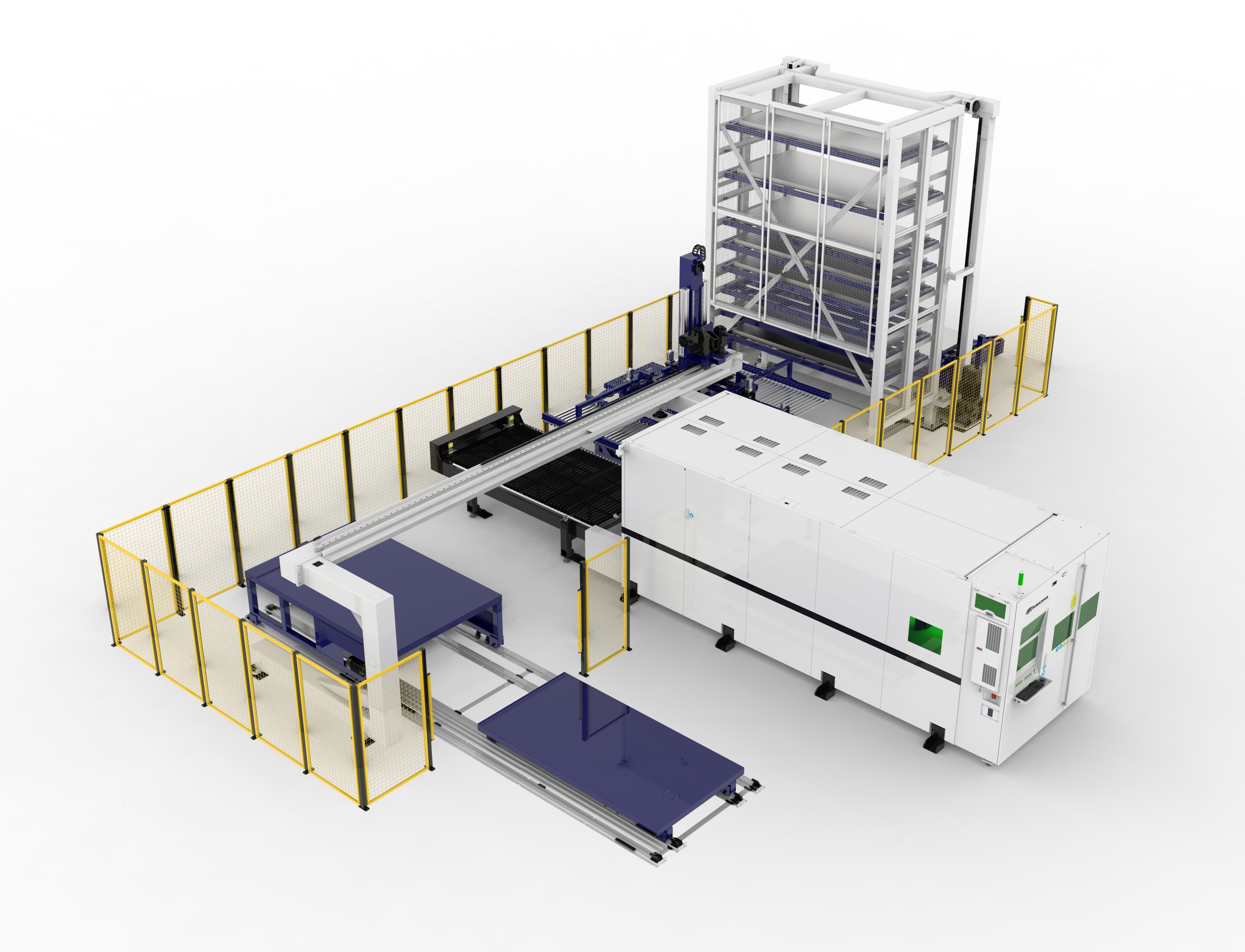

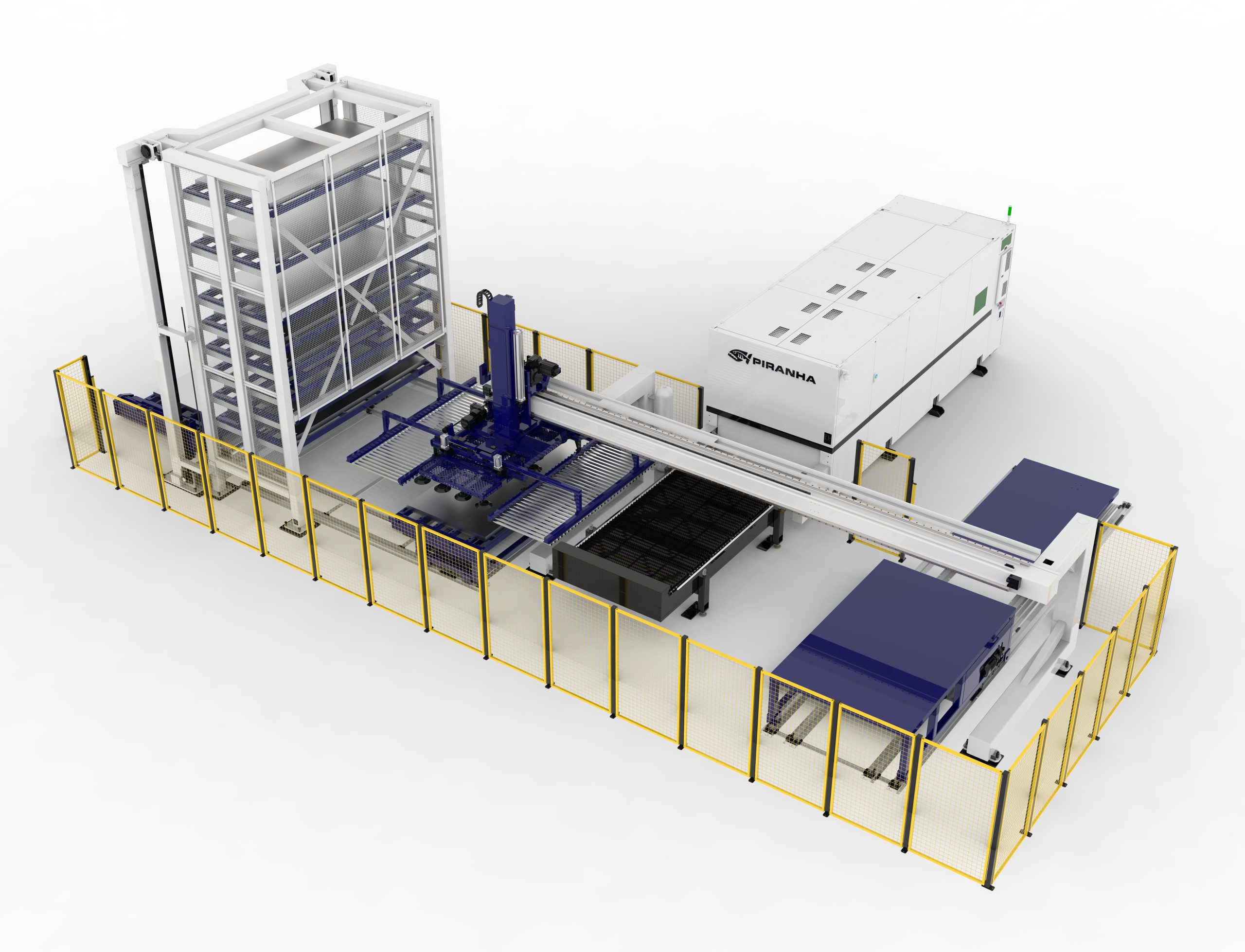

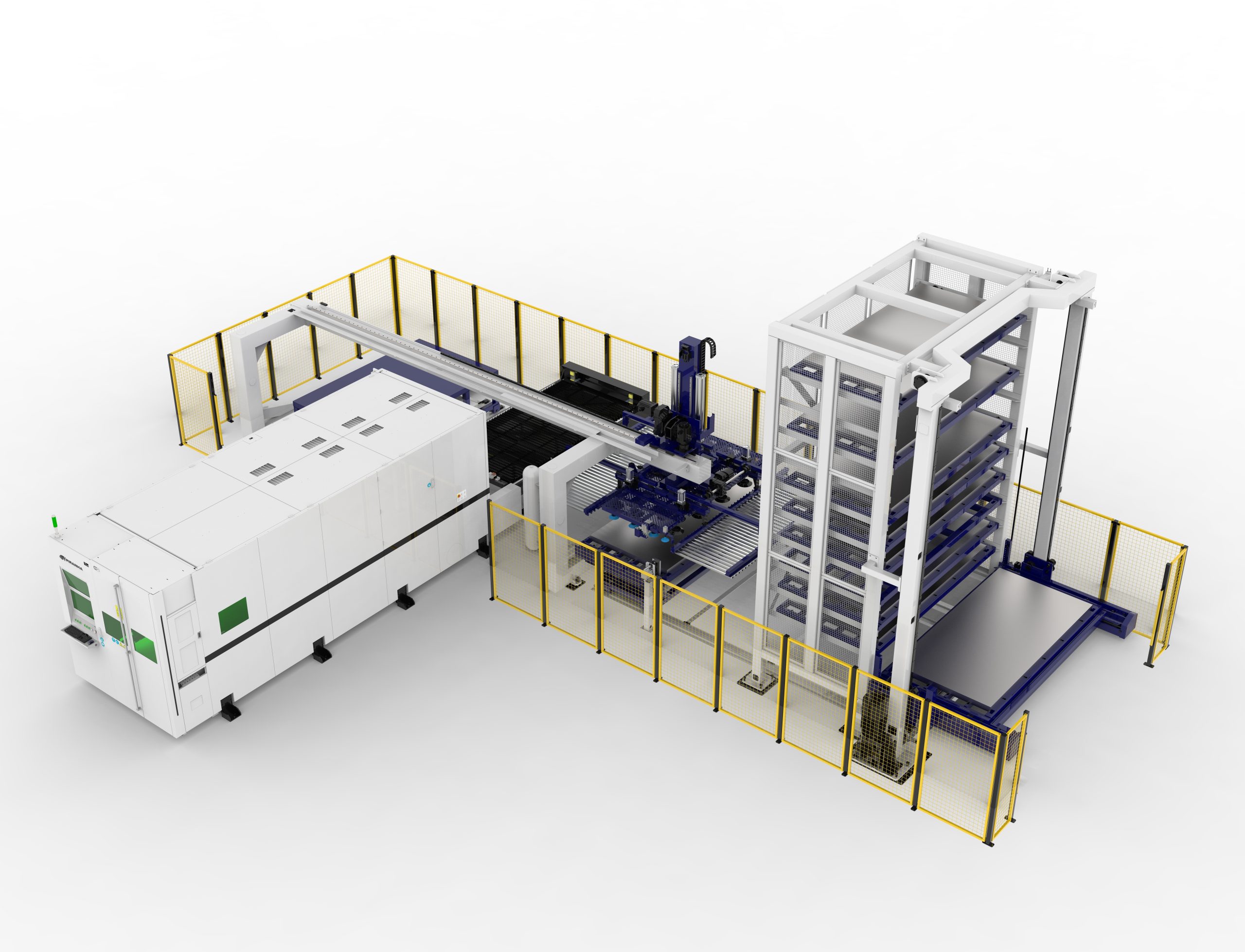

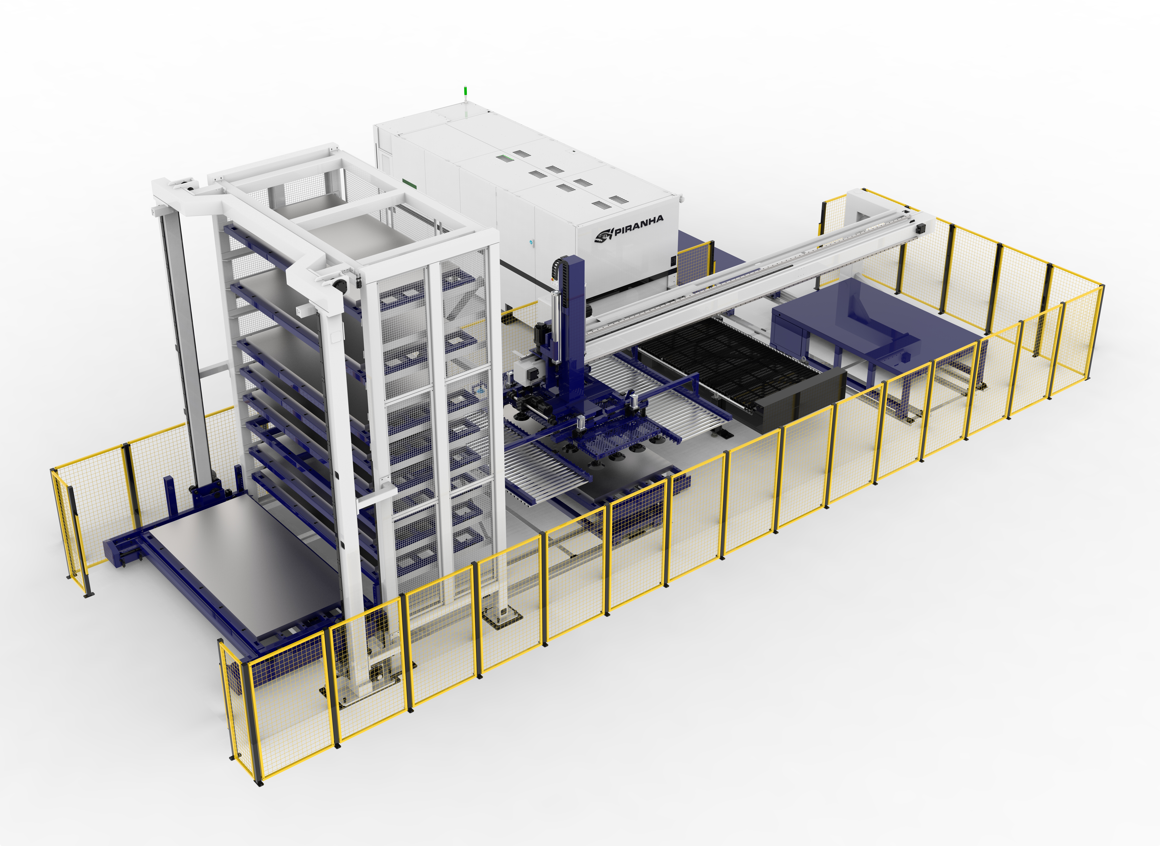

AGT Series CNC Laser Automation System with Tower

AGT Series CNC Laser Automation System with Tower

AGT Series CNC Laser Automation — Tower System

High-volume automation with multi-shelf storage and automatic sheet exchange. Configurable to fit your shop.

Request a custom AGT Series automation quote.

Share a few details below and we’ll follow up with pricing and configuration options.

Learn More

About This Piranha Product

AGT Series CNC Laser Automation Tower System

Full material storage, loading, and unloading — modular, scalable, and fully customizable.

Automate Your Entire Laser Workflow

The AGT Series is Piranha’s most advanced CNC laser automation system. It combines multi-shelf material storage with automated loading and unloading to keep your laser running with minimal operator involvement.

Whether your goal is higher throughput, reduced labor, or true lights-out production, the AGT Series gives you a fully configurable automation platform built around your workflow.

Why Add CNC Laser Automation?

Automation transforms how you cut metal:

- Increase cutting throughput and machine utilization

- Reduce manual handling, lifting, and floor movement

- Shorten changeovers and improve material flow

- Run longer, more consistent production cycles

- Support multi-shift or lights-out operation

- Future-proof your shop with modular expansion

The result: faster output, lower labor costs, and predictable daily production.

What the AGT Series Delivers

Full Tower Storage + Automated Handling

The AGT Series provides continuous access to stored sheet material and automates the entire loading/unloading process.

- Multi-shelf tower for storing multiple materials

- Automatically loads raw sheets

- Automatically unloads cut sheets and parts

- High-speed gantry for rapid material exchange

- Ideal for high-volume, mixed-material production

Built to Match Your Workflow

The AGT Series is fully customizable so you get an automation setup that fits your shop today — and can grow with you tomorrow.

Custom Configuration Options

- Tower height / number of shelves

- Material flow direction (left, right, front, rear)

- Compatible sheet sizes (4×4, 5×10, 6×12)

- Unload positions and pallet orientation

- Safety enclosure packages

- Add-on accessories and extra shelves

If your layout requires a specific footprint or workflow pattern, the AGT Series can be tailored to fit.

Designed for Continuous Production

- Multi-Shift Productivity

- The combination of tower storage and automatic sheet exchange reduces idle time and maximizes your laser’s cutting capability.

- Fast Changeovers

- Switch to different thicknesses or materials quickly — perfect for varied job queues or nested part libraries.

- Operator Efficiency

- Let the automation system handle the heavy lifting, while your team focuses on programming, part sorting, and higher-value work.

Ideal Applications

- High-volume fabrication

- Multi-material job shops

- Multi-shift or 24/7 cutting environments

- Operations needing predictable throughput

- Shops preparing for lights-out automation

General Specifications

(Final specs can be tailored to your configuration.)

- Tower Levels: 6–12 shelves

- Sheet Sizes: Supports 4×4, 5×10, and 6×12 systems

- Max Sheet Weight: 2,000–6,000 lbs depending on model

- Material Flow: Custom orientation

- Integration: Direct with Piranha Flex Series CNC laser controls

Optional Add-Ons

- Additional shelves

- Custom pallet configurations

- Extended unload stations

- Material carts and conveyors

- Safety guards and light-curtain packages

Why Piranha CNC Fiber Lasers?

Ready to Build Your Automation System?

The AGT Series can be engineered around your production goals, shop layout, and future growth.

Contact our team for pricing, layout assistance, and a custom configuration quote.