Arc Max Elite 5×10 CNC Plasma Table

Arc Max Elite 5×10 CNC Plasma Table

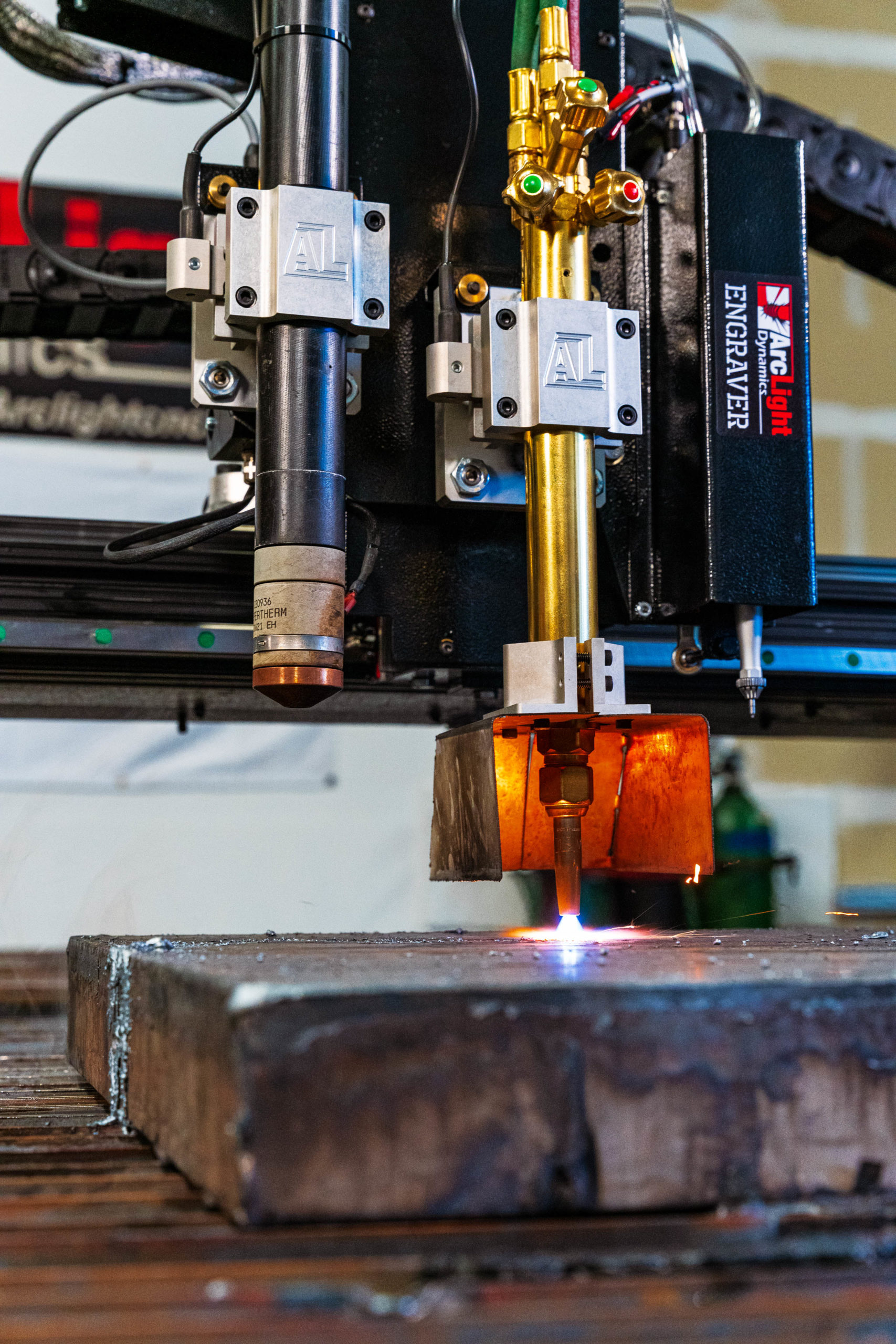

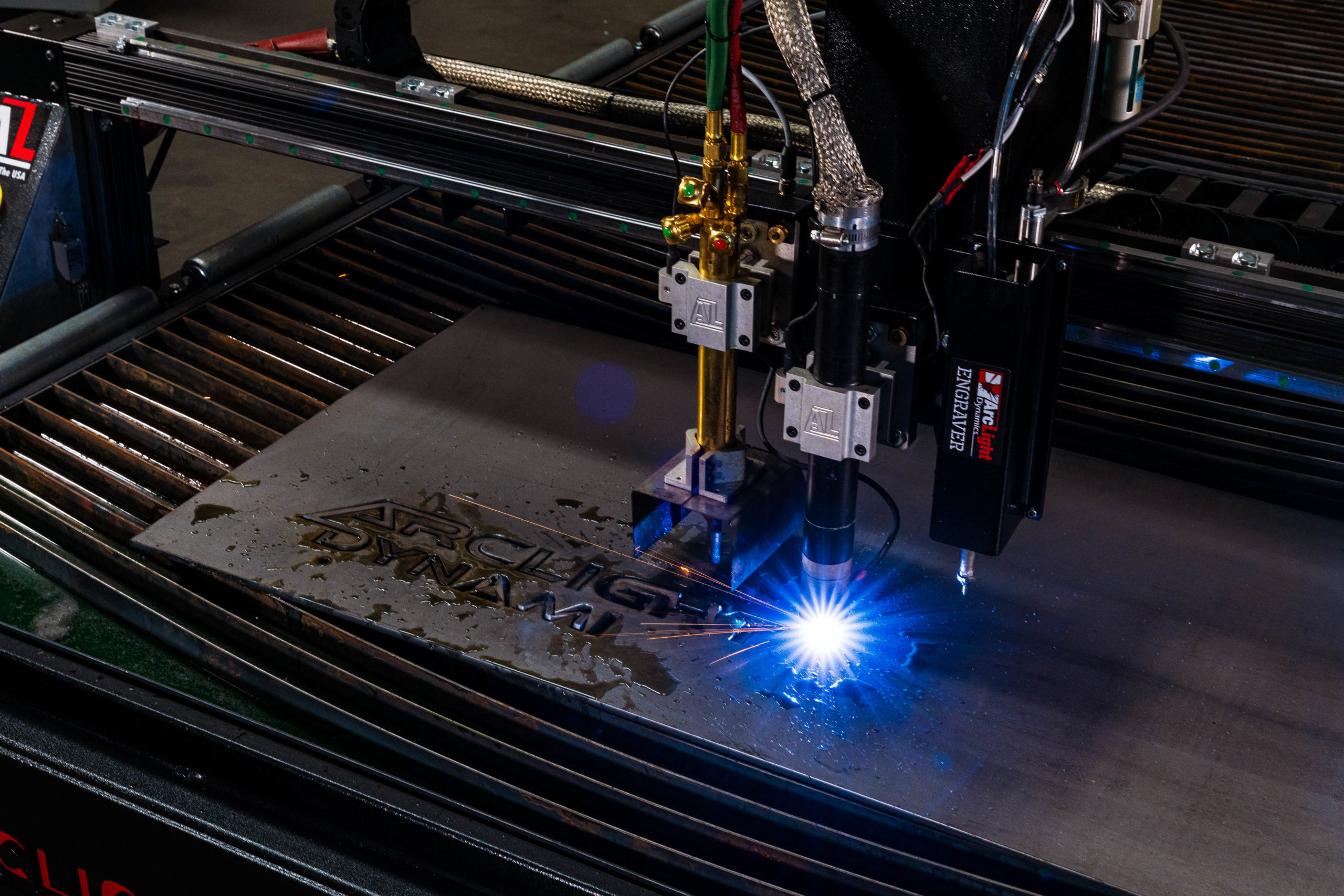

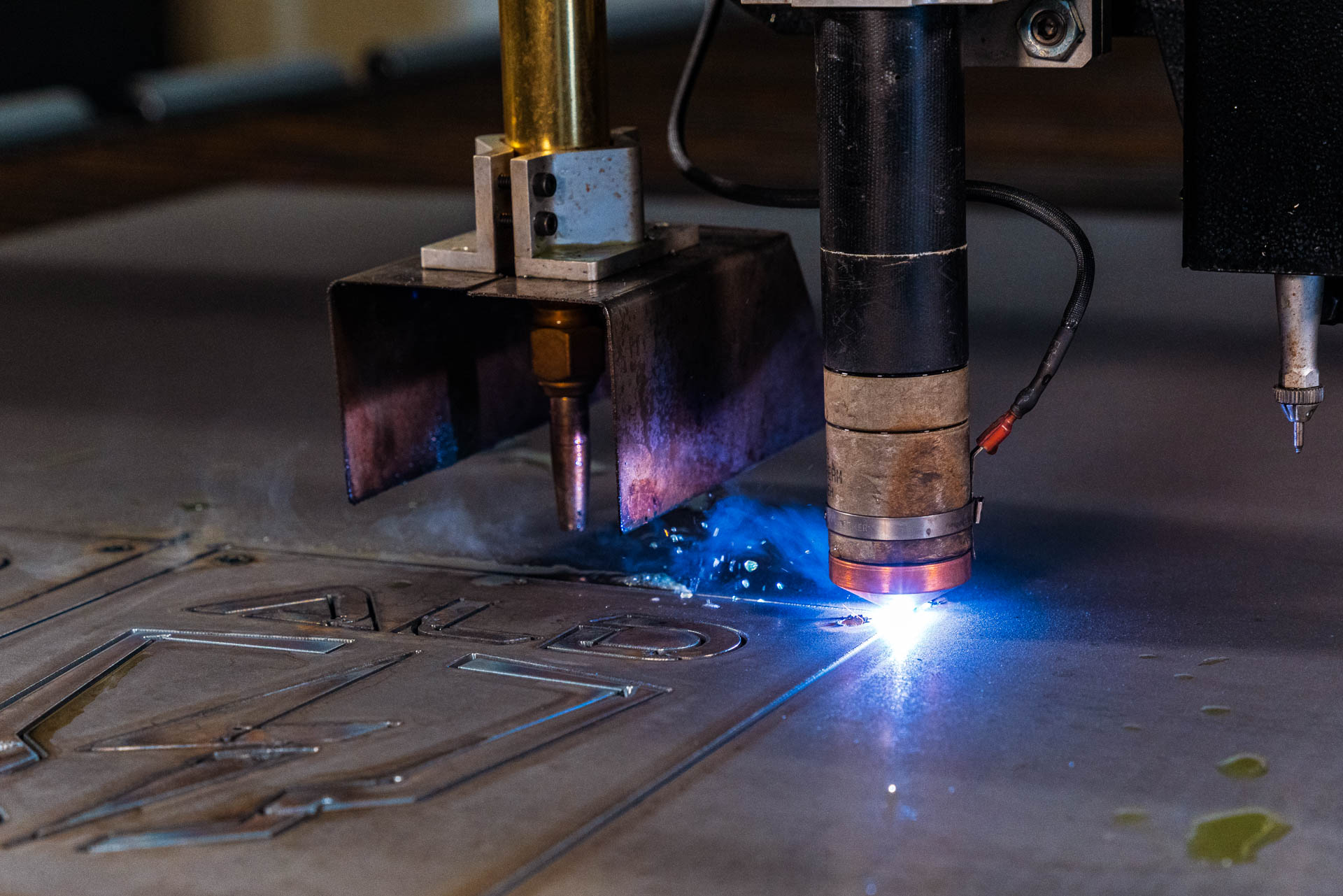

When simplified ease of use, production capability, and heavy plate processing are essential to your business’s success, our no-compromise Arc Max Elite Series of CNC plasma tables are the top-of-the-line solution for your shop. With integrated FlashCut reliability, accuracy, and efficiency are at the foundation of the design of Arc Max Elite series tables. All backed by dedicated lifetime support for a package that can not be beat.

The Arc Max Elite is built on a welded and unitized frame of thick steel tubing. The precision-designed gantry is engineered from low mass aircraft grade aluminum, providing exceptional rigidity and first-class acceleration and deceleration characteristics; most desirable in high-performance CNC plasma tables. Upgrade your shop with and Arc Max Elite CNC plasma table today.

FlashCut CNC comes standard on all Arc Max Elite tables. Decades of experience, superior features and tens of thousands of satisfied customers world-wide make FlashCut’s fully integrated CAD/CAM/CNC plasma control system among the best in the world.

In Stock and Ships in 72 Hours.

Learn More

About This Piranha Product

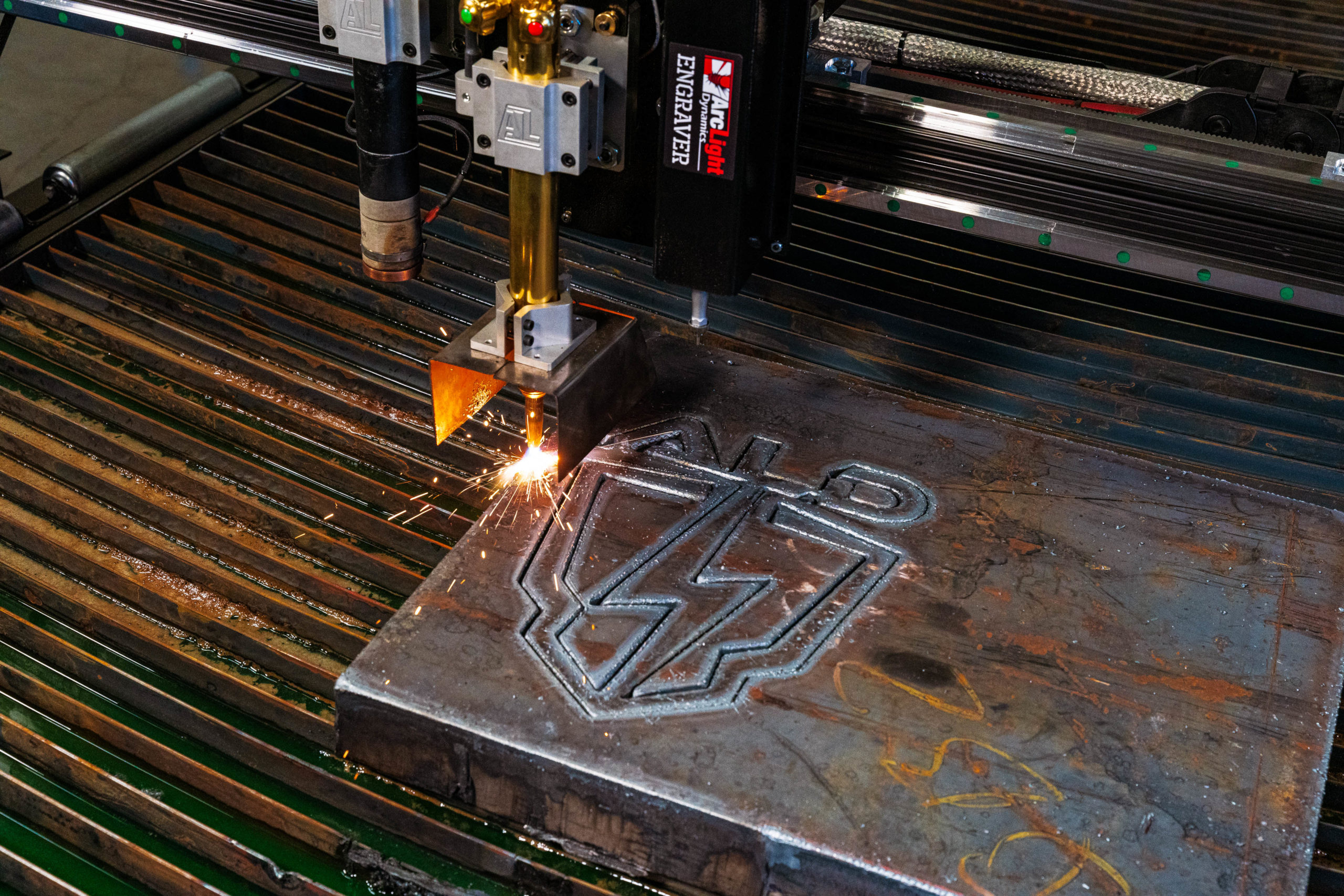

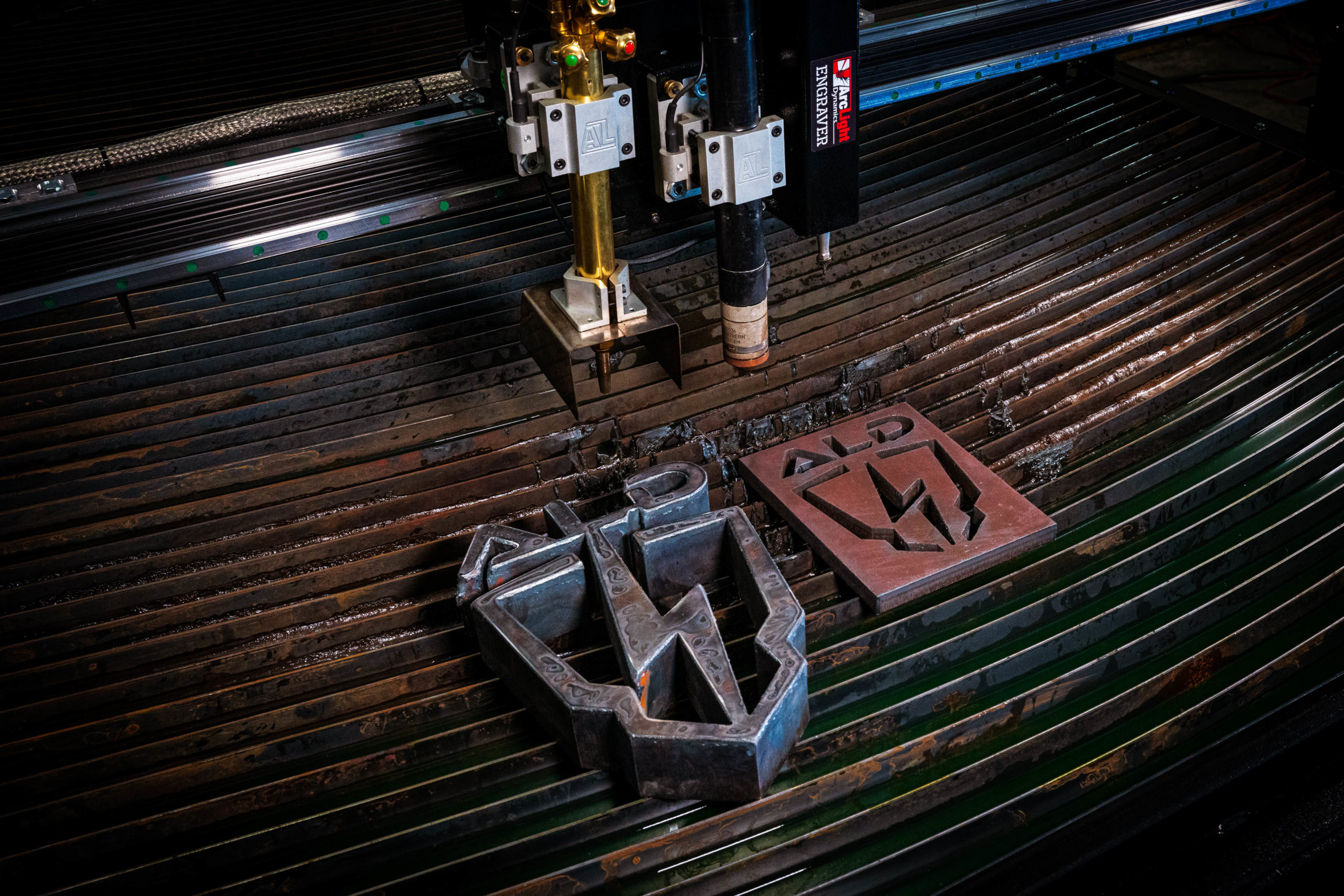

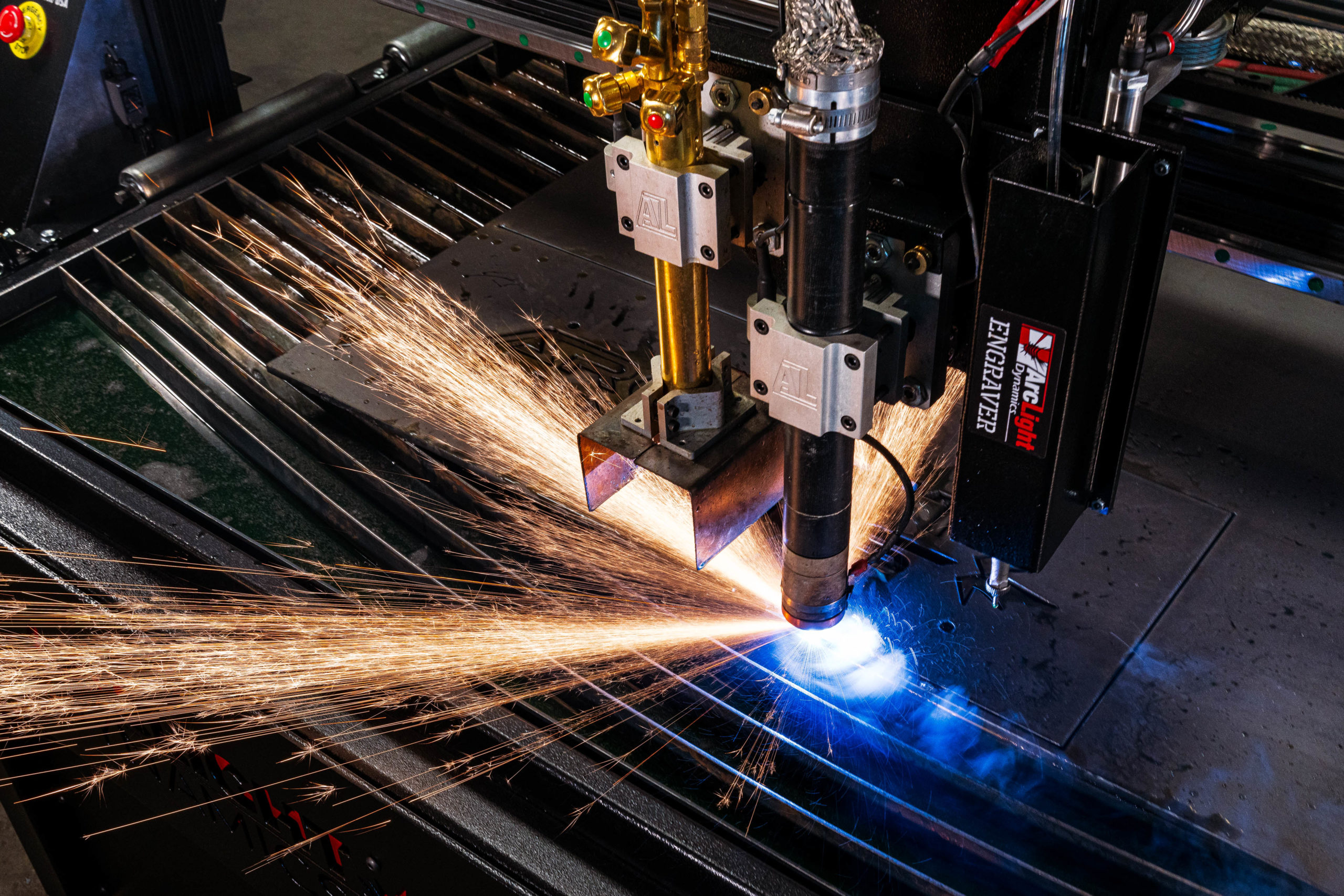

The Arc Max Elite CNC Plasma Table from Arclight Dynamics is available in 6×12, 5×10, 4×8 and 5×5. The Arc Max Elite CNC Plasma Cutting Tables have once again pushed the limits of what an air plasma cutter is capable of. We have taken the features found on high-end industrial tables and incorporated them into an affordable package. Arclight Dynamics is raising the bar for what you should expect from a CNC plasma table.

The Flashcut CNC software interface is simple and easy to run allowing anyone to walk up to the machine a cut a part with minimal effort and training. In minutes you can set up the machine to design and cut parts, allowing the operator to complete other projects.

An Arclight Dynamics CNC plasma table will be, hands down, the best investment for your shop and cost less than a part time employee. In addition, your new CNC Plasma Table will come with a full team of Arclight support technicians (Arc Angels) to assist you every step of the way.

Smooth cuts, sharp corners, and true holes. The drive system, comprised of precision 20 mm linear guide rails and Hiwin linear slide blocks, provides smooth stable motion without inducing table vibration or flex. Bottom line is Arc Max blows the doors off of the competition in cut quality and overall table performance.

Each Arc Max Elite CNC Plasma Table comes will an industry leading limited lifetime warranty on the table frame, 1 year warranty on its controller and motion control system, and a 1 year warranty on the dedicated computer.

We proudly build our CNC Plasma Tables in the United States. We believe strongly in honest business transparency without hidden fees or recurring charges.

Compare Models

Learn more about the differences of the Arc Max Elite.

| Features | Arc Max Elite | Arc Max |

| Controller | Flashcut CNC | Command CNC |

| Integrated CAD/CAM/CNC | YES | NO |

| Automatic Nesting Software | YES | NO |

| OxyFuel Ready | YES | NO |

| Work-Piece Alignment | YES | NO |

| Rapids | 800 IPM | 600 IPM |

| Motors | Nema 34- 940 oz Stepper | Nema 23- 620 oz Stepper |

| Motor Cabling | XLR Quick Connectors | Hard Wired |

| Laser Alignment | YES | Optional |

| Collision Detection | System Ready | |

| Hole Cutting | Smart 360® Hole Cutting Technology | Customizable Path Rules |

| Serial Communication | YES | Optional |

| Easy CAD/Image Import | YES | NO |

| CAD Error Fix Tool | YES | NO |

| CAD Feature Welding Tool | YES | NO |

| CAD-DXF Export | YES | NO |

| CAM 3D Cutting Simulation | YES | NO |

| CNC-THC Performance History Chart | YES | NO |

| CNC Automated Remanant Cut off | YES | NO |

| Ohmic & Mechanical Touch-Off | Both | Mechanical Only |

| CNC Automatic Lead-in on Restart | YES | NO |

HYPERTHERM PLASMA SPECIFICATIONS

POWERMAX 45XP

POWERMAX 45XP

| MATERIAL THICKNESS | MAXIMUM CUTTING SPEED | |

| 10 GA MS | 181 IPM | |

| 1/4” MS | 72 IPM | |

| 3/8” MS | 38 IPM | |

| 1/2”MS | 24 IPM | |

| GAS TYPE | AIR | NITROGEN |

| Gas Quality | Clean, dry, oil-free per ISO 8573-1 Class 1.2.2 | 99.95% pure |

| Recommended gas inlet flow and pressure | 400 scfh @ 85 psi (190 slpm @ 5.9 bar) | |

Power Connections for the Powermax 45XP (CSA Models)

| INPUT VOLTAGE | INPUT CURRENT AT RATED OUTPUT (A) | INPUT CURRENT AT ARC STRETCH (A) | FUSE/BREAKER SIZE (SLOW-BLOW) (A) |

| 200-240V SINGLE PHASE | 39 | 44 | 50A |

| 208V SINGLE PHASE | 37 | 43 | 50A |

| 480V THREE-PHASE | 9.4 | 17 | 20A |

| NOTE: Plasma table and CNC control require separate 230V single phase / 20A supply REF: Hypertherm Operator Manual 809240 Revision 1 | |||

POWERMAX 65 SmartSYNC

POWERMAX 65 SmartSYNC

| MATERIAL THICKNESS | MAXIMUM CUTTING SPEED | |

| 10 GA MS | 224 IPM | |

| 1/4” MS | 116 IPM | |

| 3/8” MS | 62 IPM | |

| 1/2” MS | 40 IPM | |

| 5/8” MS | 26 IPM | |

| GAS TYPE | AIR | NITROGEN |

| Gas Quality | Clean, dry, oil-free per ISO 8573-1 Class 1.2.2 | 99.995% pure |

| Recommended gas inlet flow and pressure | Cutting: 400 scfh @ 85 psi (190 slpm @ 5.9 bar) | |

Power Connections for the Powermax 65 (CSA Models)

| INPUT VOLTAGE | INPUT CURRENT AT RATED OUTPUT (A) | INPUT CURRENT AT ARC STRETCH (A) | FUSE/BREAKER SIZE (SLOW-BLOW) (A) |

| 200-208V SINGLE-PHASE | 52 | 74 | 80 |

| 230-240V SINGLE-PHASE | 44 | 74 | 80 |

| 480V SINGLE PHASE | 22 | 38 | 40 |

| 200-208V THREE-PHASE | 32 | 45 | 50 |

| 230-240V THREE-PHASE | 27 | 45 | 50 |

| 400V THREE-PHASE | 15 | 27 | 30 |

| 480V THREE-PHASE | 13 | 23 | 25 |

| 600V THREE-PHASE | 13 | 23 | 25 |

| NOTE: Plasma table and CNC control require separate 230V single phase / 20A supply REF: Hypertherm Operator Manual 806650 Revision 3 | |||

POWERMAX 85 SmartSYNC

POWERMAX 85 SmartSYNC

| MATERIAL THICKNESS | MAXIMUM CUTTING SPEED | |

| 10 GA MS | 336 IPM | |

| 1/4” MS | 164 IPM | |

| 3/8” MS | 80 IPM | |

| 1/2” MS | 48 IPM | |

| 5/8” MS | 30 IPM | |

| 3/4” MS | 24 IPM | |

| GAS TYPE | AIR | NITROGEN |

| Gas Quality | Clean, dry, oil-free per ISO 8573-1 Class 1.2.2 | 99.995% pure |

| Recommended gas inlet flow and pressure | Cutting: 400 scfh @ 85 psi (190 slpm @ 5.9 bar) | |

Power Connections for the Powermax 85 (CSA Models)

| INPUT VOLTAGE | INPUT CURRENT AT RATED OUTPUT (A) | INPUT CURRENT AT ARC STRETCH (A) | FUSE/BREAKER SIZE (SLOW-BLOW) (A) |

| 200-208V SINGLE-PHASE | 70 | 98 | 100 |

| 230-240V SINGLE PHASE | 60 | 98 | 100 |

| 480V SINGLE PHASES | 29 | 50 | 50 |

| 200-208V THREE-PHASE | 42 | 60 | 60 |

| 230-240V THREE-PHASE | 36 | 60 | 60 |

| 400V THREE PHASE | 21 | 38 | 40 |

| 480V THREE-PHASE | 18 | 31 | 30 |

| 600V THREE-PHASE | 17 | 30 | 30 |

| NOTE: Plasma table and CNC control require separate 230V single phase / 20A supply REF: Hypertherm Operator Manual 806650 Revision 3 | |||

POWERMAX 105 SmartSYNC

POWERMAX 105 SmartSYNC

| MATERIAL THICKNESS | MAXIMUM CUTTING SPEED | |

| 10 GA MS (85 amp process) | 336 IPM | |

| 1/4” MS | 192 IPM | |

| 3/8” MS | 116 IPM | |

| 1/2” MS | 76 IPM | |

| 5/8” MS | 52 IPM | |

| 3/4” MS | 40 IPM | |

| GAS TYPE | AIR | NITROGEN |

| Gas Quality | Clean, dry, oil-free per ISO 8573-1 Class 1.2.2 | 99.995% pure |

| Recommended gas inlet flow and pressure | Cutting: 460 scfh @ 85 psi (220 slpm @ 5.9 bar) | |

Power Connections for the Powermax 105 (CSA Models)

| INPUT VOLTAGE | INPUT CURRENT AT RATED OUTPUT (A) | INPUT CURRENT AT ARC STRETCH (A) | FUSE/BREAKER SIZE (SLOW-BLOW) (A) |

| 200V THREE-PHASE | 58 | 82 | 80 |

| 208V THREE-PHASE | 56 | 82 | 80 |

| 240V THREE-PHASE | 49 | 78 | 80 |

| 480V THREE-PHASE | 25 | 40 | 40 |

| 600V THREE-PHASE | 22 | 35 | 40 |

| NOTE: Plasma table and CNC control require separate 230V single phase / 20A supply REF: Hypertherm Operator Manual 817390 Revision 2 | |||

POWERMAX 125

POWERMAX 125

| MATERIAL THICKNESS | MAXIMUM CUTTING SPEED | |

| 10 GA MS (65 amp process) | 296 IPM | |

| 1/4” MS | 225 IPM | |

| 3/8” MS | 138 IPM | |

| 1/2” MS | 93 IPM | |

| 5/8” MS | 66 IPM | |

| 3/4” MS | 48 IPM | |

| GAS TYPE | AIR | NITROGEN |

| Gas Quality | Clean, dry, oil-free per ISO 8573-1 Class 1.2.2 | 99.995% pure |

| Recommended gas inlet flow and pressure | Cutting: 550 scfh @ 85 psi (260 slpm @ 5.9 bar) | |

Power Connections for the Powermax 125 (CSA Models)

| INPUT VOLTAGE | INPUT CURRENT AT RATED OUTPUT (A) | INPUT CURRENT AT ARC STRETCH (A) | FUSE/BREAKER SIZE (SLOW-BLOW) (A) |

| 480V THREE-PHASE | 31 | 50 | 50 |

| 600V THREE-PHASE | 24 | 38 | 40 |

| NOTE: Plasma table and CNC control require separate 230V single phase / 20A supply REF: Hypertherm Operator Manual 808080 Revision 3 | |||

Hypertherm SmartSYNC Plasma Torches (STANDARD on 65, 85, and 105A systems)

SmartSYNC torches feature RFID capability that when coupled with a Hypertherm cartridge will communicate with a Powermax SYNC system to automatically set the amperage and process on the power supply.

The Hypertherm cartridge consumable platform is a revolutionary change to standard air plasma consumables. Each single-piece cartridge is optimized by process and amperage to ensure performance while dramatically simplifying the parts needed to cut or gouge with plasma.

Hypertherm cartridges for Powermax systems are manufactured to uphold our high standards for quality and reliability. As part of the manufacturing process, we test-fire each cartridge to ensure proper assembly and function. As a result, there may be burn marks on the tip of the cartridge. This is normal and not a sign of damage.

*Table displayed with additional options and accessories.