CNC Fiber Laser Automation Systems

What Automation Delivers

Piranha CNC laser automation systems help you move material faster, reduce manual handling, and keep your laser cutting consistently throughout the day. Whether you need full tower storage, a load/unload gantry, or a simple lift-assist arm, each system integrates with your Piranha fiber laser and can be configured to fit your space and workflow. The result is smoother production, less operator strain, and more cutting time on every shift.

-

Faster material loading and unloading

-

Less manual lifting and operator fatigue

-

More consistent production throughout the day

-

Shorter changeovers between jobs and materials

-

Better use of your laser’s cutting capacity

-

Scalable options to grow with your shop

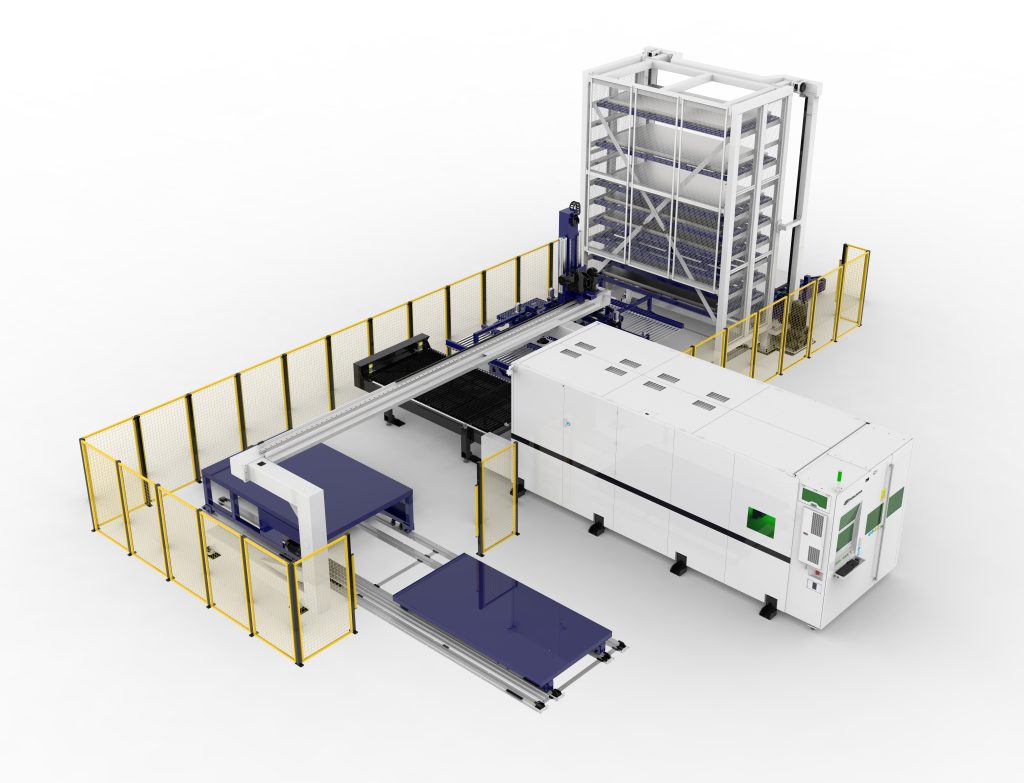

AGT Series – CNC Laser Automation Tower System

Full storage, loading, and unloading for maximum throughput.

A high-capacity tower system that stores multiple materials and automates the entire sheet-exchange cycle. Ideal for high-volume cutting, mixed materials, and multi-shift or lights-out production. Fully customizable for your layout and workflow.

Best for: High-volume shops, multiple materials, continuous cutting.

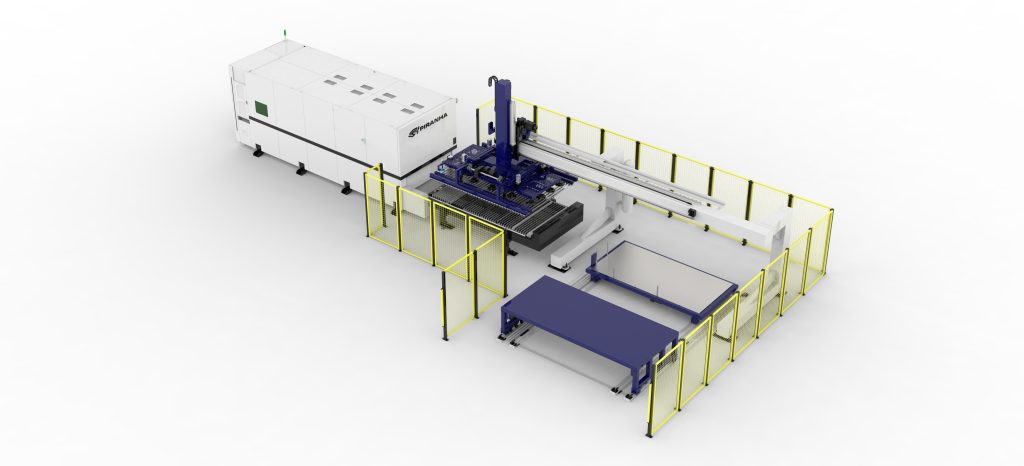

AG Series – CNC Laser Automation Load/Unload System

Fast, automated sheet loading and unloading in a compact footprint.

A gantry-based system that loads raw sheets and unloads finished parts without tower storage. Great for floor-staged material and reducing operator handling. Boosts throughput without the space or investment of vertical storage.

Best for: Growing shops, floor-staged material, faster daily throughput.

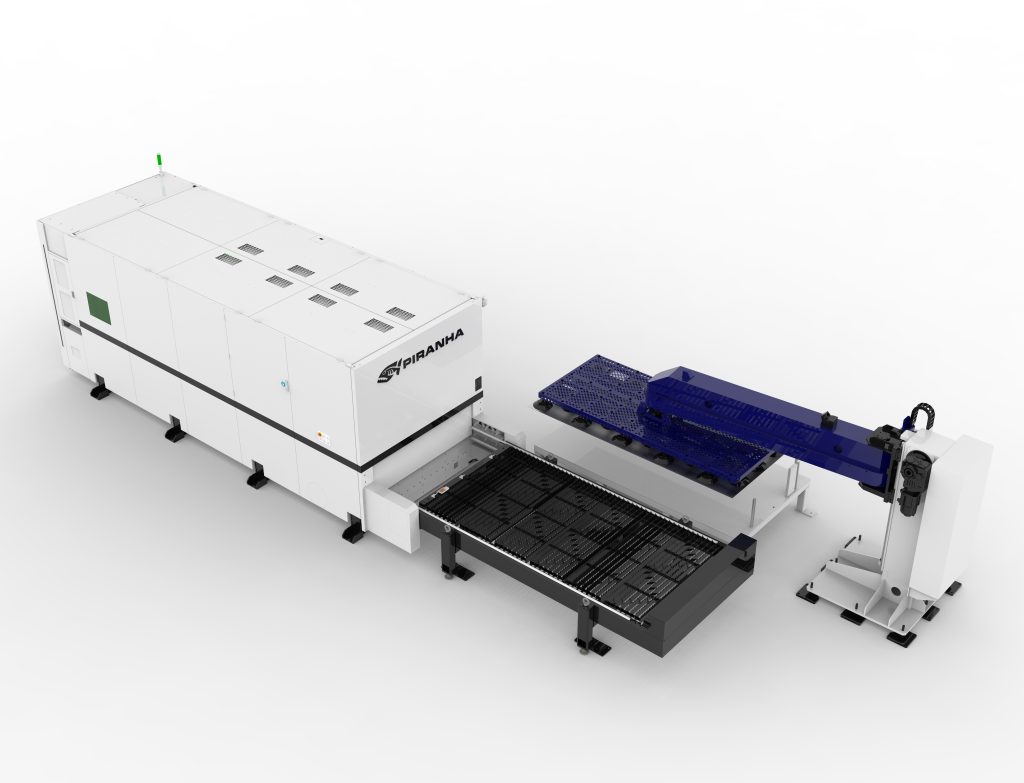

LA Series – CNC Laser Automation Pivoting Loading Arm

Simple, affordable lift-assist loading for tighter shop spaces.

A compact pivoting arm that helps operators lift and position sheet material quickly and safely. A smart first step into automation that reduces strain and speeds up job setup.

Best for: Small to mid-size shops, limited space, reducing manual lifting.

Fast and Efficient

Ready to boost your laser’s productivity?

Our team can help you choose the right automation system and configure it for your shop.

Our CNC fiber LASER Cutting History

Our CNC LASER Cutting Machines Background

Whitney (now Piranha-Whitney) has been designing and building CNC LASERs since their inception.

- 1980: In 1980, the first Whitney CO2 LASER was sold.

- 1986: In 1986, a combination punch LASER FMS system including 128 punching tools, material loading and unloading, and part removal was installed and put into production.

- 1993: The move toward flying option LASER led to the Whitney LG3300 CO2 gantry LASER in 1993.

- 1999: The PlateLASER 6000 was the first 6kW CO2 LASER to market in 1999, soon followed by the 10’ x 20’ 7kW PlateLASER-II.

- 2013: Piranha-Whitney introduced the first 6kW fiber LASER with the PlateLASER fiber in 2013.

- 2016: Piranha-Whitney introduced the 12kW PlateLASER 1530 in 2016.

- 2020: Piranha-Whitney offers a wide range of CNC fiber LASER cutters starting with E-Series CNC fiber LASER (1kW, 2kW, or 3kW), moving up in capabilities and power is our L-series CNC fiber LASER (1kW to 4kW), then the M-series CNC fiber LASER (4 to 6kW), and the most powerful and capable P-series CNC fiber LASER (4 to 12kW high speed).

- 2023: Piranha introduces the new FLEX Series LASER, in sizes from 5’x10′ to 8’x20′ and LASER powers from 3kW to 20kW.

- 2024: Piranha introduces the new 5×10 Single Pallet Series LASER, in powers of 3kW and 6kW.

- 2025: Piranha introduces the new 4×4 Single Pallet Series LASER, in powers of 3kW and 6kW.

Fabrication Equipment

Thermal Cutting Machines

Current Promotions & In Stock

Contact Piranha

- 775 Logistics Dr, Belvidere, IL 61008

- Toll Free: 800-338-5471

- Local: 815-964-6771