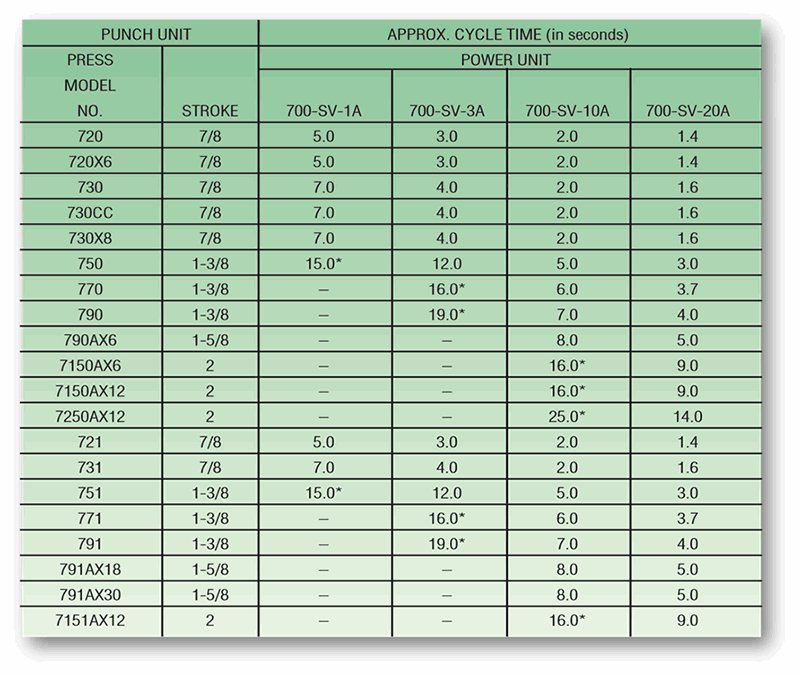

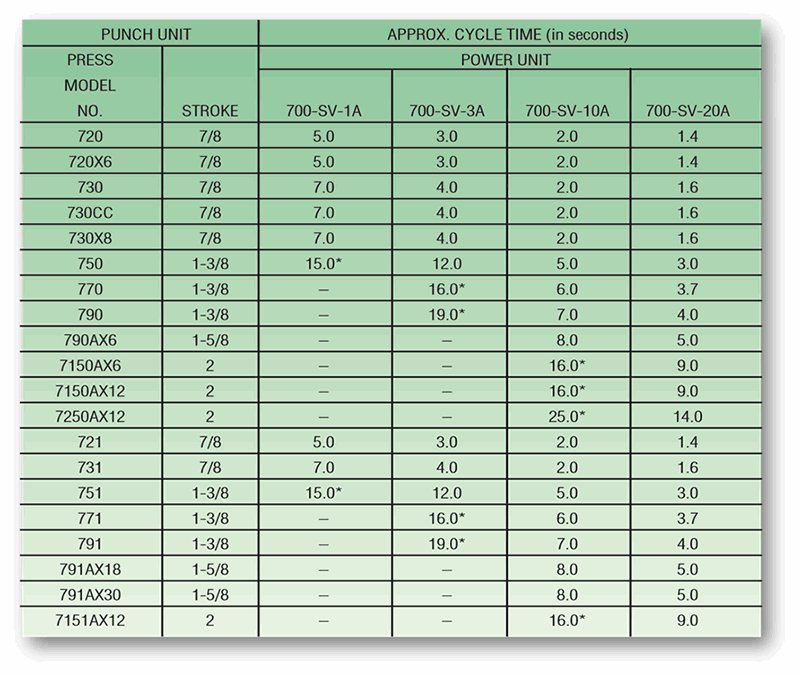

Each portable press operates from a hydraulic Power Unit. These power units have an operating pressure of 5000 psi and are available in four different sizes.

Determining the Correct Hydraulic Power Unit

The basic difference between these models is the volume of oil each is capable of delivering to the press. This is further determined by the size of the pump motor. As a basic rule of thumb, the more horse power—the faster the press cycle time.

Two-Stage: The 1-1/2 HP hydraulic power unit is a two-stage type that delivers maximum flow at low pressures up to 1,000 psi and reduced flow up to 5,000 psi.

Single Stage: The 3, 10 and 20 HP hydraulic power units are all fixed displacement, or single stage, types. Fixed displacement power units are considered to be ideal for single hole punching where it is necessary to jog or inch the punch down for locating to a center punch mark. With this type of power unit, the oil is delivered at a fixed rate regardless of the operating pressure. This means that the ram on the press will travel at the same speed throughout the entire punching cycle. (The return cycle will be slightly faster due to the cylinder displacement differential.)

The size of the power unit required for any given application is determined by how fast you want the unit or units to cycle. The cycle time is shown using a full stroke of the press. When punching thinner material, it is not necessary to use the full stroke of the press, therefore, the cycle time will be faster.

* Cycle time may be slower for some applications For gang punch application consult factory

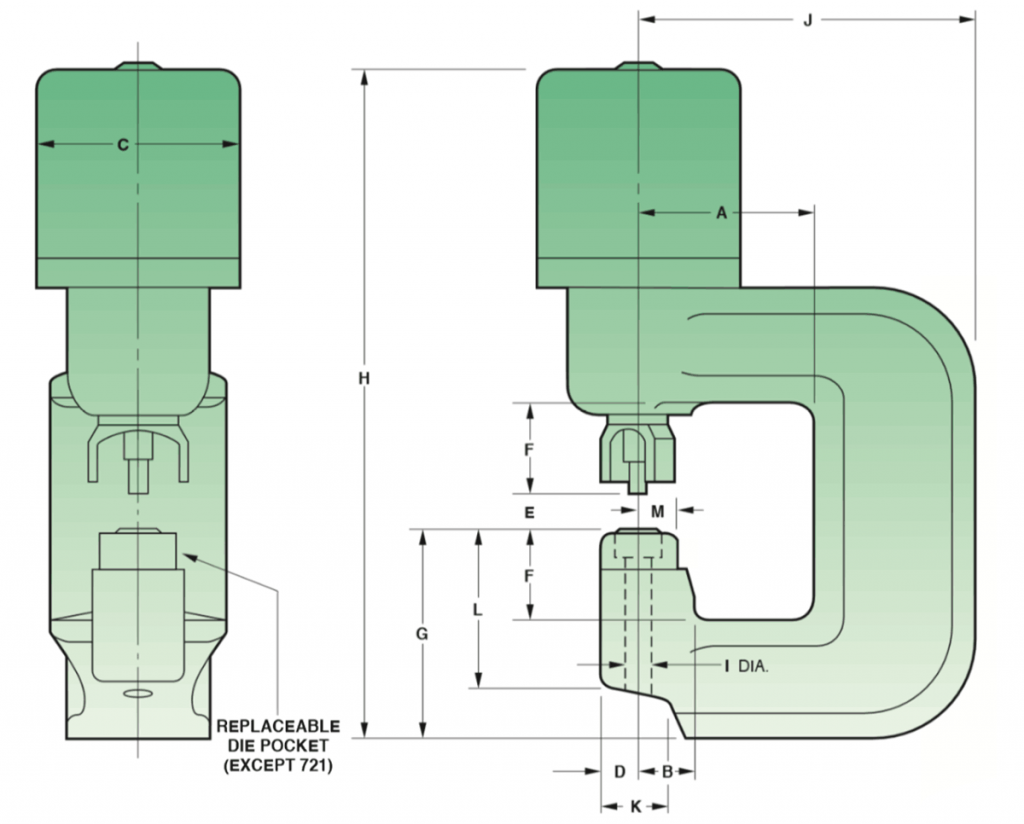

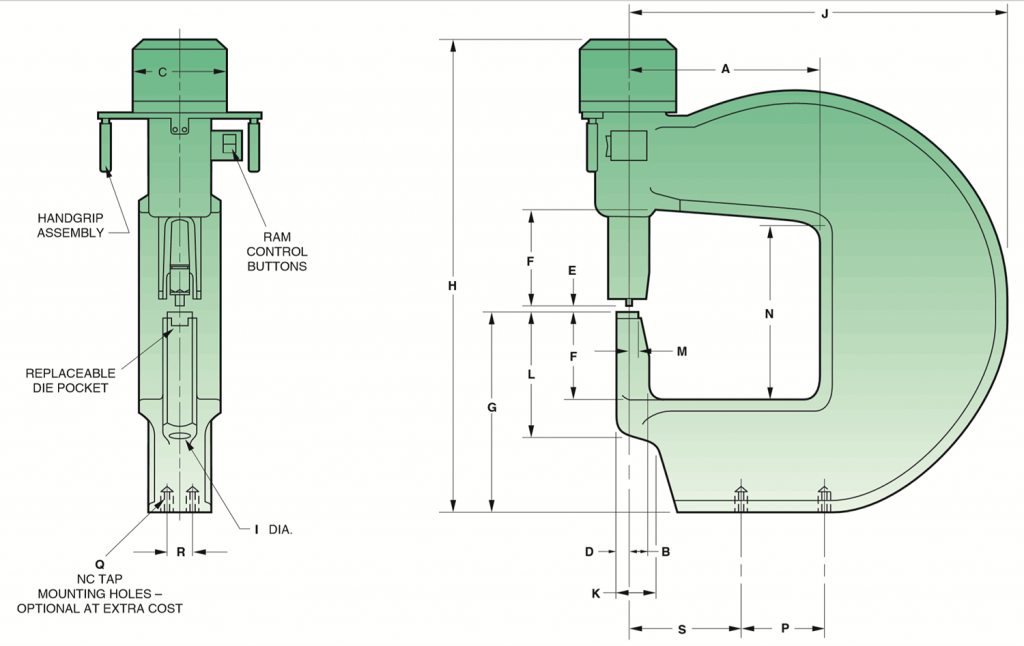

Note: All dimensions are in inches.

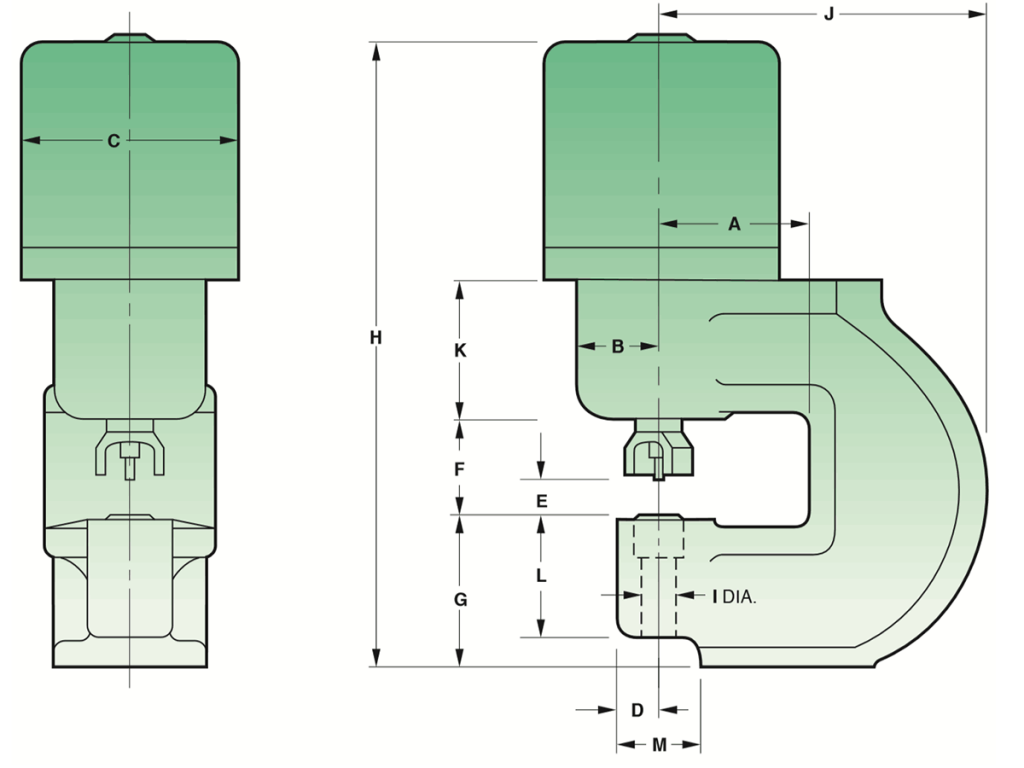

Note: All dimensions are in inches. Note: All dimensions are in inches.

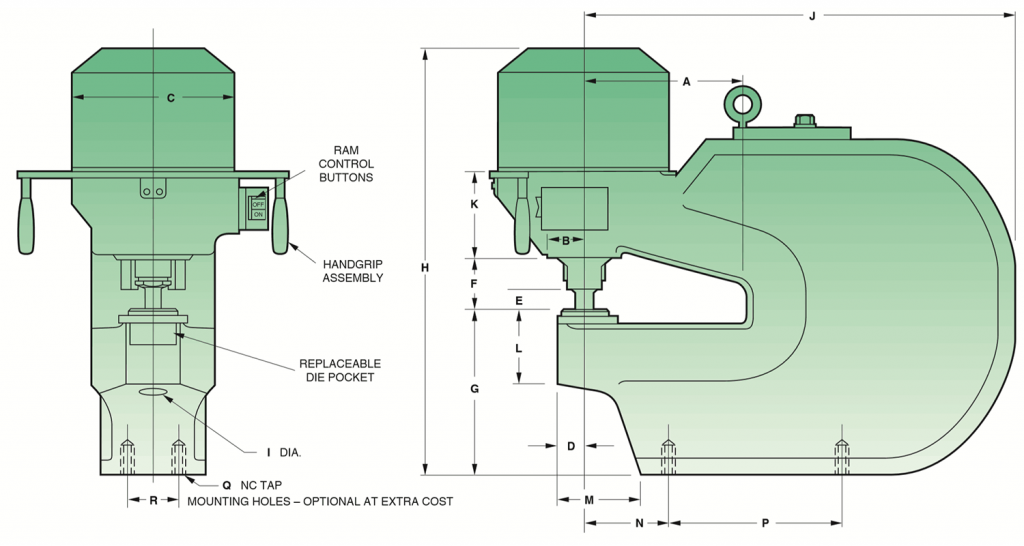

Note: All dimensions are in inches. Note: All dimensions are in inches.

Note: All dimensions are in inches. Note: All dimensions are in inches.

Note: All dimensions are in inches.