Bertsch Bending Rolls

Our Bertsch plate roller lines have their roots in the long history of the Bertsch name, which has earned worldwide recognition as the leader in the manufacturing of innovative, heavy-duty metal rolling equipment.

Unparalleled Service

With Piranha’s acquisition of Bertsch in 2003, Bertsch customers can now take advantage of our unparalleled customer service.

Our Bertsch bending rolls can roll to 1.1 times top roll diameter. They also can pre-bend at rated rolling capacity.

Serious Advantages

Other advantages of our Bertsch bending rolls include:

- More pre-bend

- Minimum rolling diameter at maximum material thickness/width

- Designed for long life

- Quality parts

- Easier to use

- Higher capacity

Built to handle the most severe applications, our custom plate rollers deliver power and precision for materials up to 14” thick.

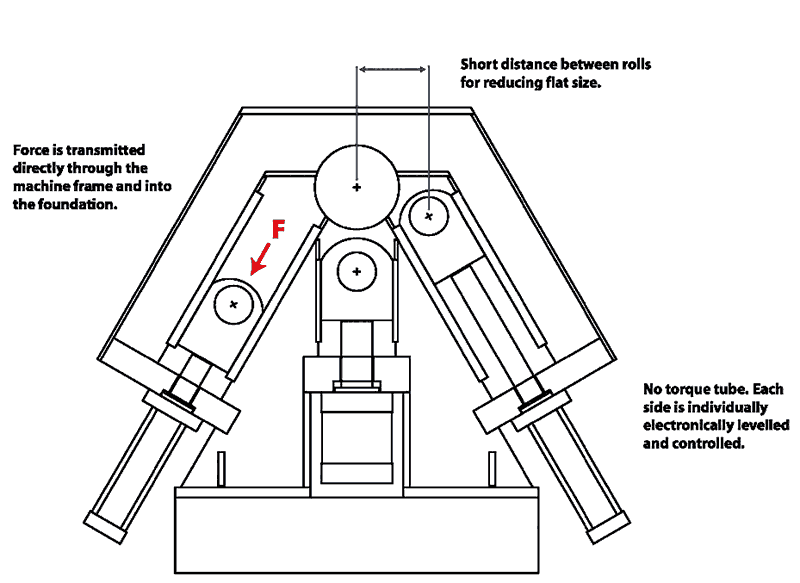

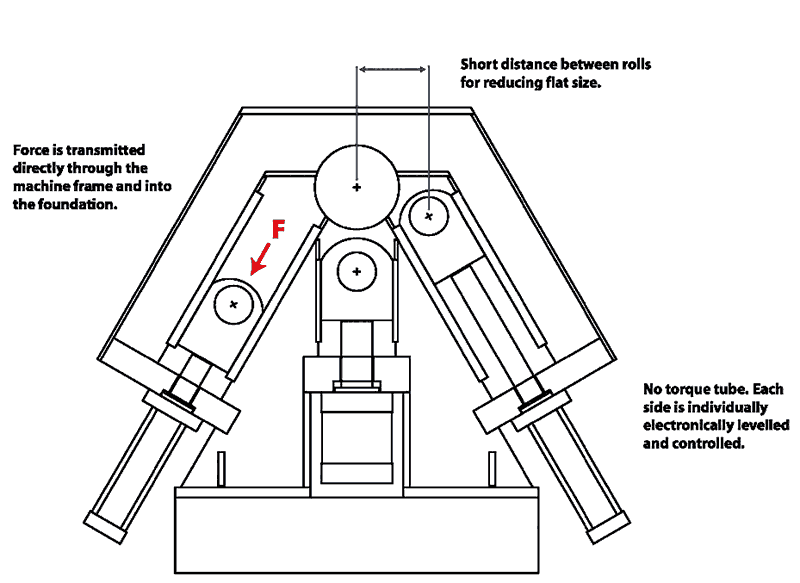

Rectilinear Guides

Rectilinear guides and electronic roll leveling are the foundations of our reputation for long-lasting heavy-duty rolls. The Rectilinear Guide concept consists of forming rolls that are guided in place by a machined surface, and bearing blocks mounted directly above the hydraulic cylinder. The position of the rolls is controlled by the hydraulic cylinder with no additional moving parts.

Our rectilinear guide system transmits the forming roll forces directly to the hydraulic cylinder, into the machine frame, and into the foundation. There are no load-bearing wear points or torsional stresses affecting roll parallelism and accuracy. This leads to a long service life, consistent parts, and low maintenance. The centerline of the forming roll is close to that of the pinch roll. This allows the flat areas associated with pre-bending to be small and consistent. In addition, we size the direct-acting hydraulic cylinders to pre-bend to the maximum rolling capacity of each machine.

Each side of every forming roll is individually controlled, allowing fine roll adjustments, making cone rolling easy to set up. There are no torque tube stresses to account for.

Pre-bending to the full rated capacity plate is accomplished with sufficient power in each side roll hydraulic cylinder. Many competitors are not capable of pre-bending to their maximum rated rolling capacity.

Rolls are easily adjusted on either end with Bertsch’s unique electronic leveling system. Roll corrections are more difficult on competitors’ plate rolling machines because they allow adjustment on one end only.

Higher Bending Capacity

Bertsch Rolls have higher capacities than “equivalent” competitive rolls:

- Bertsch sizes its rolls for bending ASTM A36 material. A36 has a minimum yield strength of 36,000 psi. However, the specification has no upper limit, and most A36 steel has yield strength of significantly more than this minimum specification. Because of this, Bertsch sizes its rolls for material with a yield strength of 49,000 psi.

- Most competitive rolls show technical specifications that are based on a yield strength of only 37,000 psi. This barely covers the minimum specification for A36, and certainly does not have a reasonable factor of safety for steel conforming to this standard.

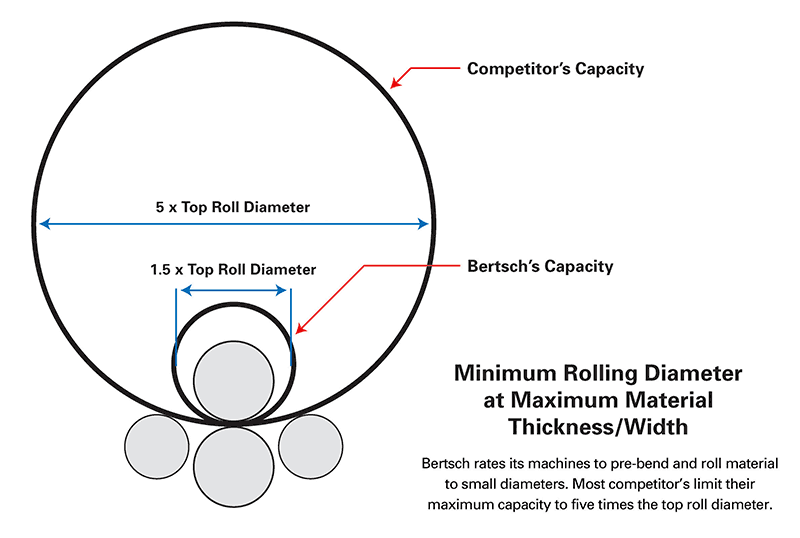

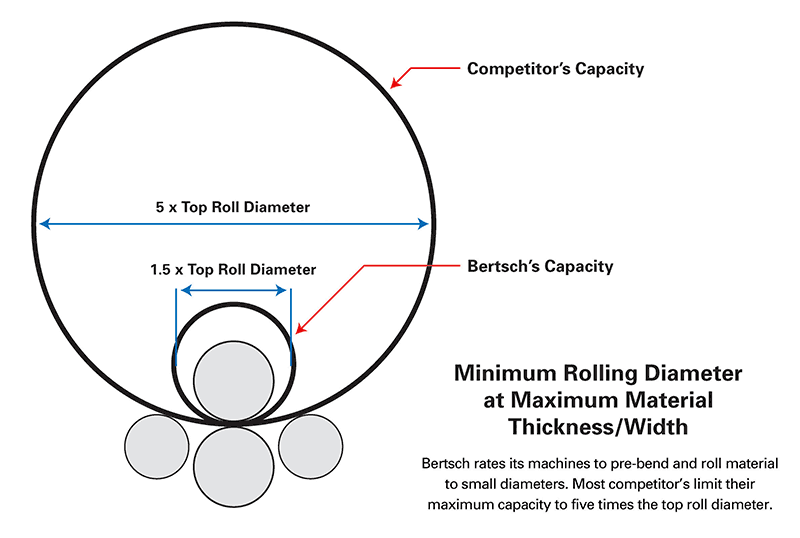

- Bertsch rolls are capable of forming maximum material thicknesses to much smaller diameters than most competitors. While most manufacturers specify a minimum roll diameter of 5x top roll diameter for maximum thickness and width, Bertsch rolls are capable of rolling maximum thickness and width to 1.5 times top roll diameter. In many cases, the next size smaller Bertsch roll has the same rolling capacity as a competitor’s roll.

Operator Controls

Operator controls are located on movable pendant or console for ease of use. We offer a range of control units—from manual/digital readout consoles to an NC control console.

The Bertsch NC control unit features a 15″ color touch screen display and provides proportional control of rotation and all roll movements. Programs can be created by editing individual blocks or by inserting actual roll positions by using the teach functionality as you roll.

A blended radius can be programmed by programming two axes in one block and a comments section is displayed so that the operator can make notes about the job to help verify the program at a later date.

Remote service and diagnostics are available via network connection, and the system provides virtually unlimited job storage via internal memory, usb or network connection.

Note: The NC Control is designed to manage the machines axes. How material reacts to these positions can vary greatly with changes in the materials dimensions and mechanical properties. Therefore, modifications to program positions are often required to adjust for these variables.

Optional Equipment and Enhancements

- Overhead & side supports – Recommended when rolling larger diameters. Hydraulically adjustable and used to maintain cylinder shape during rolling.

- Cone rolling attachment – The attachment is a removable snubber device, designed to retard the small end of the cone, allowing the large end to travel at a greater surface speed.

- Alloy hardened rolls – Recommended when forming cones or when rolling hard materials that may leave permanent scarring in the roll surface.

- Material feed systems – Custom designed for rolling application to reduce labor.

- Plate travel monitor – Linear encoder measures plate travel, as a digital readout indicates plate location. Used when rolling parts requiring a flat prior to a radius.

- Electronic speed control – Infinitely variable roll rotation speed provided directly from operations console.

- Polished & ground rolls – For applications where surface is critical and minimal defects are allowed.

- Custom rolls – Custom designs to fit every rolling need, from rolling corrugated material to automated cells.

Rolling Process Comparison

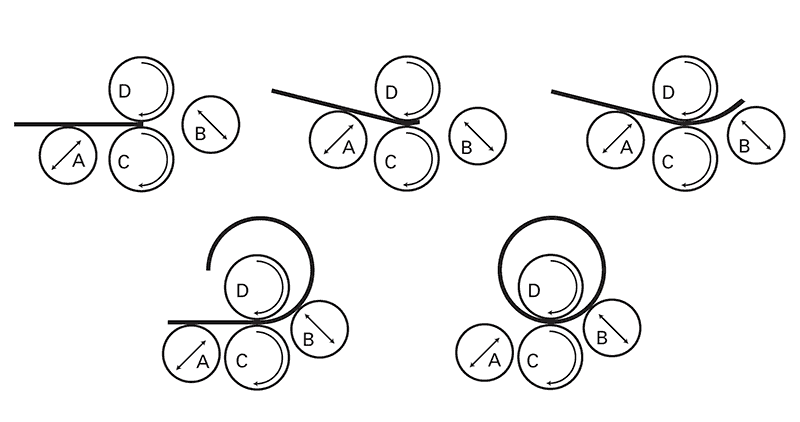

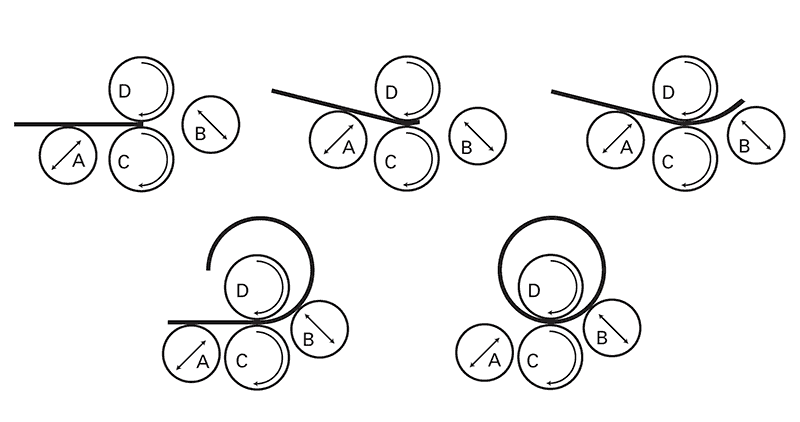

Piranha-Bertsch offers a complete line of hydraulic roll bending machines: four-roll double pinch, three-roll initial pinch, and the three-roll double pinch.

Four-Roll Double Pinch

- Easiest machine to operate since material is clamped during the squaring process and held during the entire rolling process.

- Able to pre-bend, roll and post-bend the entire piece without releasing the pinch, allowing some parts to be pre-bent and the entire cylinder rolled in a single pass.

- Because the plate is clamped through the entire bending cycle, a rotary encoder can be utilized to indicate how much plate has been fed through the machine, allowing it to be fitted with an optional CNC control.

- Material is fed into the machine parallel to the floor, easily fitted with feed tables and side supports, or placed into a pit for ease of operation.

- Less floor space is required because the part is rolled up and over right after the first pre-bend.

- Machine can be fed from either direction.

Three-Roll Initial Pinch

- Ability to pre-bend material to minimize flat.

- Able to bump form easily.

- Requires less floor space than three roll double pinch (both ends of the plate are preformed from the same side of the machine).

- Able to square plate prior to rolling.

- Machine can be easily fitted with feed tables, material supports, or set in a pit.

- Material remains square throughout the entire rolling process once it is squared and pinched between the pinching rolls.

- May require operator to remove plate from machine and rotate 180 degrees to pre-bend trailing edge of plate if the part requires pre-bending on both ends.

Three-Roll Variable Axis

- This style machine can pre-bend both ends and roll the plate by feeding the material only once.

- Eliminates the need to flip the plate around.

- Allows for greater “rolling capacity” with the ability to spread the lower rolls apart which increases the centerline distance.

- Material is fed into the machine parallel to the floor, easily fitted with feed tables and side supports.

- Horizontally mounted lower roll cylinders allow for a lower plate entry height.

- The machine can be fed from either direction.