Piranha A-Series Plasma Cutting Tables

The superior durability of Piranha with a economical entry point.

- Models:

- Piranha A505 (5’x5′ Cutting Area)

- Piranha A510 (5’x10′ Cutting Area)

INCLUDED FEATURES

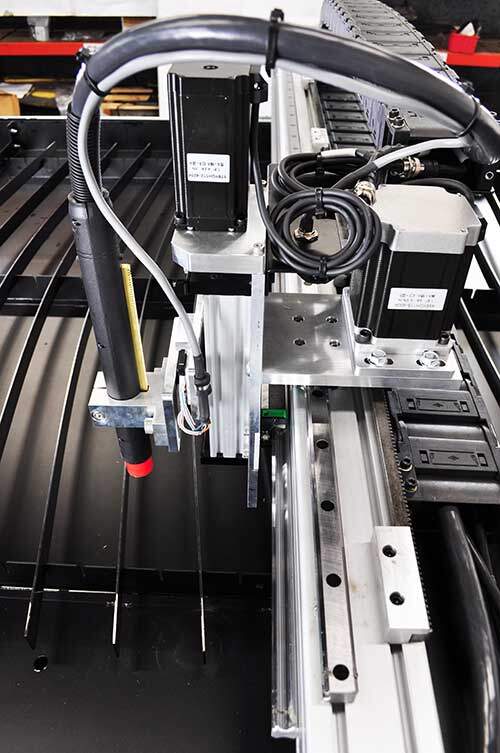

- Rugged Construction – Simple and rugged bolted table with high-accuracy linear guides and bearings.

- Dual Side Drive – gantry driven on both sides for maximum stability

- CNC Control (Laptop required) – software download included

- Stepper motors and drives – Stepper motors on both X-axis and Y-axis with a maximum traverse speed of 600in/min.

- Water table slag collection – eliminates need for dust collector.

- Programmable Torch Height Control – controls torch height automatically

- Homing Kit – allows for quick and easy homing of the torch location and utilizes sensors so the torch cannot overtravel and cause damage.

- MyPlasm CNC Software – download included, or software is preloaded if you purchase the optional laptop with a machine.

NOTE: Additional full CAD/CAM software is available for purchase if 2D CAD drawing and additional nesting capabilities are needed. See options list for ProNest® LT details.

AVAILABLE PLASMA SYSTEMS

- Powermax 45XP: 1/2” (12mm) Production / 1/2” (12mm) Maximum (mild steel)

- Powermax 65 SmartSYNC: 5/8” (16mm) Production / 5/8” (16mm) Maximum (mild steel)

- Powermax 85 SmartSYNC: 3/4” (20mm) Production / 3/4” (20mm) Maximum (mild steel)

- Powermax 105 SmartSYNC: 3/4” (20mm) Production / 7/8” (22mm) Maximum (mild steel)

- Powermax 125: 3/4” (20mm) Production / 1” (25mm) Maximum (mild steel)

MACHINE SPECIFICATIONS

| FEATURE |

SPECIFICATION |

| Maximum Rapid Speed |

600 IPM |

| CNC Control |

PC – Windows 10 or higher* |

| Frame and Bridge Construction |

Aluminum & Steel – Fabricated bolt together |

| Drive Motors |

X-axis – Two Stepper Motors

Y-axis – Stepper Motor

Torch Height Control – Stepper Motor |

| Drive System |

X-axis – Rack and Pinion each side

Y-axis – Rack and Pinion

Z-axis – Ball Screw |

| Torch Control |

Arc Voltage with Initial Height Sensing |

HYPERTHERM PLASMA SPECIFICATIONS

POWERMAX 45XP

POWERMAX 45XP

| MATERIAL THICKNESS |

MAXIMUM CUTTING SPEED |

| 10 GA MS |

181 IPM |

| 1/4” MS |

72 IPM |

| 3/8” MS |

38 IPM |

| 1/2”MS |

24 IPM |

| GAS TYPE |

AIR |

NITROGEN |

| Gas Quality |

Clean, dry, oil-free per ISO 8573-1 Class 1.2.2 |

99.95% pure |

| Recommended gas inlet flow and pressure |

400 scfh @ 85 psi (190 slpm @ 5.9 bar) |

Power Connections for the Powermax 45XP (CSA Models)

| INPUT VOLTAGE |

INPUT CURRENT AT RATED OUTPUT (A) |

INPUT CURRENT AT ARC STRETCH (A) |

FUSE/BREAKER SIZE (SLOW-BLOW) (A) |

| 200-240V SINGLE PHASE |

39 |

44 |

50A |

| 208V SINGLE PHASE |

37 |

43 |

50A |

| 480V THREE-PHASE |

9.4 |

17 |

20A |

| NOTE: Plasma table and CNC control require separate 230V single phase / 20A supply

REF: Hypertherm Operator Manual 809240 Revision 1 |

POWERMAX 65 SmartSYNC

POWERMAX 65 SmartSYNC

| MATERIAL THICKNESS |

MAXIMUM CUTTING SPEED |

| 10 GA MS |

224 IPM |

| 1/4” MS |

116 IPM |

| 3/8” MS |

62 IPM |

| 1/2” MS |

40 IPM |

| 5/8” MS |

26 IPM |

| GAS TYPE |

AIR |

NITROGEN |

| Gas Quality |

Clean, dry, oil-free per ISO 8573-1 Class 1.2.2 |

99.995% pure |

| Recommended gas inlet flow and pressure |

Cutting: 400 scfh @ 85 psi (190 slpm @ 5.9 bar) |

Power Connections for the Powermax 65 (CSA Models)

| INPUT VOLTAGE |

INPUT CURRENT AT RATED OUTPUT (A) |

INPUT CURRENT AT ARC STRETCH (A) |

FUSE/BREAKER SIZE (SLOW-BLOW) (A) |

| 200-208V SINGLE-PHASE |

52 |

74 |

80 |

| 230-240V SINGLE-PHASE |

44 |

74 |

80 |

| 480V SINGLE PHASE |

22 |

38 |

40 |

| 200-208V THREE-PHASE |

32 |

45 |

50 |

| 230-240V THREE-PHASE |

27 |

45 |

50 |

| 400V THREE-PHASE |

15 |

27 |

30 |

| 480V THREE-PHASE |

13 |

23 |

25 |

| 600V THREE-PHASE |

13 |

23 |

25 |

| NOTE: Plasma table and CNC control require separate 230V single phase / 20A supply

REF: Hypertherm Operator Manual 806650 Revision 3 |

POWERMAX 85 SmartSYNC

POWERMAX 85 SmartSYNC

| MATERIAL THICKNESS |

MAXIMUM CUTTING SPEED |

| 10 GA MS |

336 IPM |

| 1/4” MS |

164 IPM |

| 3/8” MS |

80 IPM |

| 1/2” MS |

48 IPM |

| 5/8” MS |

30 IPM |

| 3/4” MS |

24 IPM |

| GAS TYPE |

AIR |

NITROGEN |

| Gas Quality |

Clean, dry, oil-free per ISO 8573-1 Class 1.2.2 |

99.995% pure |

| Recommended gas inlet flow and pressure |

Cutting: 400 scfh @ 85 psi (190 slpm @ 5.9 bar) |

Power Connections for the Powermax 85 (CSA Models)

| INPUT VOLTAGE |

INPUT CURRENT AT RATED OUTPUT (A) |

INPUT CURRENT AT ARC STRETCH (A) |

FUSE/BREAKER SIZE (SLOW-BLOW) (A) |

| 200-208V SINGLE-PHASE |

70 |

98 |

100 |

| 230-240V SINGLE PHASE |

60 |

98 |

100 |

| 480V SINGLE PHASES |

29 |

50 |

50 |

| 200-208V THREE-PHASE |

42 |

60 |

60 |

| 230-240V THREE-PHASE |

36 |

60 |

60 |

| 400V THREE PHASE |

21 |

38 |

40 |

| 480V THREE-PHASE |

18 |

31 |

30 |

| 600V THREE-PHASE |

17 |

30 |

30 |

| NOTE: Plasma table and CNC control require separate 230V single phase / 20A supply

REF: Hypertherm Operator Manual 806650 Revision 3 |

POWERMAX 105 SmartSYNC

POWERMAX 105 SmartSYNC

| MATERIAL THICKNESS |

MAXIMUM CUTTING SPEED |

| 10 GA MS (85 amp process) |

336 IPM |

| 1/4” MS |

192 IPM |

| 3/8” MS |

116 IPM |

| 1/2” MS |

76 IPM |

| 5/8” MS |

52 IPM |

| 3/4” MS |

40 IPM |

| GAS TYPE |

AIR |

NITROGEN |

| Gas Quality |

Clean, dry, oil-free per ISO 8573-1 Class 1.2.2 |

99.995% pure |

| Recommended gas inlet flow and pressure |

Cutting: 460 scfh @ 85 psi (220 slpm @ 5.9 bar) |

Power Connections for the Powermax 105 (CSA Models)

| INPUT VOLTAGE |

INPUT CURRENT AT RATED OUTPUT (A) |

INPUT CURRENT AT ARC STRETCH (A) |

FUSE/BREAKER SIZE (SLOW-BLOW) (A) |

| 200V THREE-PHASE |

58 |

82 |

80 |

| 208V THREE-PHASE |

56 |

82 |

80 |

| 240V THREE-PHASE |

49 |

78 |

80 |

| 480V THREE-PHASE |

25 |

40 |

40 |

| 600V THREE-PHASE |

22 |

35 |

40 |

| NOTE: Plasma table and CNC control require separate 230V single phase / 20A supply

REF: Hypertherm Operator Manual 817390 Revision 2 |

POWERMAX 125

POWERMAX 125

| MATERIAL THICKNESS |

MAXIMUM CUTTING SPEED |

| 10 GA MS (65 amp process) |

296 IPM |

| 1/4” MS |

225 IPM |

| 3/8” MS |

138 IPM |

| 1/2” MS |

93 IPM |

| 5/8” MS |

66 IPM |

| 3/4” MS |

48 IPM |

| GAS TYPE |

AIR |

NITROGEN |

| Gas Quality |

Clean, dry, oil-free per ISO 8573-1 Class 1.2.2 |

99.995% pure |

| Recommended gas inlet flow and pressure |

Cutting: 550 scfh @ 85 psi (260 slpm @ 5.9 bar) |

Power Connections for the Powermax 125 (CSA Models)

| INPUT VOLTAGE |

INPUT CURRENT AT RATED OUTPUT (A) |

INPUT CURRENT AT ARC STRETCH (A) |

FUSE/BREAKER SIZE (SLOW-BLOW) (A) |

| 480V THREE-PHASE |

31 |

50 |

50 |

| 600V THREE-PHASE |

24 |

38 |

40 |

| NOTE: Plasma table and CNC control require separate 230V single phase / 20A supply

REF: Hypertherm Operator Manual 808080 Revision 3 |

CUSTOMER PROVIDED PLASMA SYSTEMS

Piranha can integrate existing air plasma systems up to 125A. The customer must provide details and specifications on the existing air plasma system for review before Piranha can approve the integration. There will be a minimum charge of $1,000 for systems not supplied by Piranha. Charges for additional components, cables, and shipping may be required after review. Piranha will not provide any warranty on the existing system and will not guarantee the cut quality.

PLASMA CUTTING SPEEDS

Plasma cutting speed cannot exceed the maximum cutting speed of 600 IPM (15240 mm/min). Recommended cutting speeds in the Hypertherm Powermax cut charts will be limited to a maximum of 600 IPM.

Hypertherm SmartSYNC Plasma Torches (STANDARD on 65, 85, and 105A systems)

SmartSYNC torches feature RFID capability that when coupled with a Hypertherm cartridge will communicate with a Powermax SYNC system to automatically set the amperage and process on the power supply.

The Hypertherm cartridge consumable platform is a revolutionary change to standard air plasma consumables. Each single-piece cartridge is optimized by process and amperage to ensure performance while dramatically simplifying the parts needed to cut or gouge with plasma.

Hypertherm cartridges for Powermax systems are manufactured to uphold our high standards for quality and reliability. As part of the manufacturing process, we test-fire each cartridge to ensure proper assembly and function. As a result, there may be burn marks on the tip of the cartridge. This is normal and not a sign of damage.

Powermas65, Powermax85, and Powermax105 plasma systems come with SmartSYNC torches as standard equipment.

Powermax45XP and Powermax125 plasma systems are not available with SmartSYNC torches.

PC REQUIREMENTS FOR CNC CONTROL

The PC needed for the CNC control software can be provided by Piranha (optional) or by the customer. The following minimum requirements must be met.

| ITEM |

MINIMUM REQUIREMENT |

| Operating System |

Windows 10 Pro for Business |

| Processor Family |

AMD 3000 Series or Intel Core i3-6100 |

| RAM |

8 GB |

| Internal Storage |

128 GB SSD |

| Display |

14″ HD (1366 x 768) |

| Input |

Full-size keyboard with Touchpad |

| Communications |

Wi-Fi 802.11a/b/g/n/ac, Bluetooth 5 |

| Ports |

(1) USB Type-A (1) USB Type-C |

MyPlasm CNC Software (INCLUDED)

MyPlasm CNC software includes everything needed to control the machine and the automated torch height control. The software can be installed on a laptop you provide or can be pre-installed if the Piranha provided laptop is purchased. It includes a DXF import function so you can quickly and easily pull in and cut parts utilizing a clean line connected DXF (or similar supported file type). Cut parameters can be set and saved within this windows-based program. MyPlasm software is simple to learn and to operate. With a minimum level of knowledge, operators can learn that with a few clicks they can cut a part directly from the DXF. They can also draw simple shapes in the MyMini CAD module, included for free.

MyPlasm is windows based software that allows operators to quickly cut parts without the need to learn coding or complex control settings. You can simulate cut paths to help position your material correctly on the table prior to cutting and resume cut paths easily. Torch homing , cut parameters, torch height, and lead in – lead out settings are all easily accessed from the home screen.

ProNest® LT Smart Start (OPTIONAL)

ProNest® CAD/CAM software is available for purchase if 2D CAD drawing and additional nesting capabilities are needed.

Hypertherm ProNest® LT Smart Start is a powerful CAD/CAM nesting software designed for light industrial, mechanized cutting in production environments. It provides a single software solution for all your conventional plasma cutting machines. ProNest® LT Smart Start helps fabricators and manufacturers increase material savings, boost productivity, reduce operating costs, and improve part quality by offering the right level of cutting expertise for your needs. It also supports Hypertherm SureCut™ technology, including easy setup, optimized process parameters, and easy trouble shooting. In addition, ProNestLT® Smart Start is backed by Hypertherm’s global network of professionals, meaning you’ll always have access to the service and support you need.

| FEATURE |

BENEFIT |

| Part design and development |

- Integrated 2D CAD program to create and edit CAD files

- Variable Shape Parts feature to develop common parts from templates

|

| CAD/CAM import and conversion |

- Import CAD files (industry-standard file formats)

- Raster to vector converts static images to CAD

- Automatic CAD file correction and error notification

- Automatic spline/ellipse smoothing and reduction

- Separate multiple parts from a single CAD file

- Automatic mapping of CAD layers to processes (cut, mark)

|

| Job Set-Up |

- Material database (with grade and gauge)

- Custom remnant creation (define irregular shapes for nesting)

- Grain constraint

- Safe zones for plate clamping applications

|

| SureCut™ technology and built-in process expertise |

- Material type, thickness, grade and class-based process parameters:

- Separations for part, plate, and pierce spacing

- Kerf compensation and feed rate

- Lead-in/out style optimized for part geometry and quality

- Cutting techniques

- Cut sequencing – automatic or manual

|

| Interactive manual nesting |

- Group parts into clusters for nesting

- Color parts according to part property

- Drag, drop, bump, and auto-bump parts on the nest

- Move, mirror, and drag to rotate parts

- Click and drag to automatically array parts

- Prohibit/permit nesting inside of a part

- Part interference detection

- Edit lead-in/out position and properties within the nest

- Animated cutting sequence simulation

- Control cut direction and cut sequencing on part-by-part basis

- Plate cropping

|

| Detailed reporting |

- Management and shop reports

- Export reports directly to PDF, Excel spreadsheet, CSV, or webpage

|

ProNest® Essentials (OPTIONAL)

Includes:

Automatic Nesting – nest with the click of a button. Choose a preferred nesting strategy to control the balance between nesting speed and material utilization or select “IntelliChoice” and ProNest will determine a strategy and nest. Parts are nested for maximum cutting efficiency and material utilization, without any operator intervention required.

ProNest® Unlimited (OPTIONAL)

Includes:

Automatic Nesting – nest with the click of a button. Choose a preferred nesting strategy to control the balance between nesting speed and material utilization or select “IntelliChoice” and ProNest will determine a strategy and nest. Parts are nested for maximum cutting efficiency and material utilization, without any operator intervention required.

Common Line Cutting – share the common edges of adjacent parts. This feature can be applied automatically to similar parts or manually for dissimilar part profiles. Kerf compensation is applied automatically. Fewer pierces and reduced cutting distance will maximize productivity and consumable life. It also can save material by eliminating the separation between parts that otherwise becomes scrap.

Chain and Bridge Cutting – link multiple part profiles into one continuous cut. The chain can be created manually, after parts have been nested, or automatically as an array of parts. Use Bridge Cutting to create a thin web of material between parts, which helps prevent tip‑ups on small parts. This forms a single exterior profile, which can stabilize parts during separation from the plate, making them less prone to the effects of thermal movement. Both techniques result in fewer pierces and greater consumable life.

Skeleton Cut-Up – makes dedicated cuts to a sheet, making it easier to remove skeleton material from the table. Skeleton cuts are added automatically; and can be edited to meet your needs. Skeleton lines may be cut before or after the parts are cut.

Design2Fab® Sheet Metal Layout Software (OPTIONAL)

Design2Fab sheet metal layout software makes it easy to create HVAC duct, mechanical, kitchen, industrial, roofing, and other specialty fitting layouts. Engineered to dramatically reduce the time it takes to develop and lay out flat patterns, Design2Fab provides sheet metal fabricators, HVAC shops, and MEP contractors with the ability to create complex custom fitting layouts in minutes, rather than hours. Design2Fab also helps ensure perfect fit-up when installing parts in the field, contributing to increased productivity and lower operating costs to accomplish more, while increasing profitability.

Starting with the parametric fittings library, you will have access to a complete range of templates including all core shapes and sizes which can be customized to virtually any design. You can apply SMACNA or DIN based shop standards to any fitting in the job, including pressure class, metal gauge, seam styles, joints, stiffeners, wrap, acoustic liner, and sealant. Once the design is complete, it can export patterns to DXF for automated cutting. You can also export patterns for manual cutting using HPGL print files, printed to a plotter, or laid out manually using XY or triangulation points.

- Comprehensive fittings library with unlimited customization

- 3D view verification of fittings

- 2D layout view of pattern fitting

- Job manager for multi-level zones

- Copy fitting or zone

- Fully customizable shop standards

- Based on SMACNA and DIN standards

- DXF export for nesting and automated cutting

- HPGL export for printing and manual cutting

- Custom seam and joint types

- Custom list of liners, wrap, sealant, stiffeners, vanes, and hangers

- Shear list – blank sizes calculated

- Fitting list – quick list of fittings in job

- Detail list – shop ticket format shows fitting, details, and dimensions

- Shear list – blank sizes calculated

- Multiple reports

TRAINING

All Piranha training will require a minimum of one-week advance notice.

Training on Hypertherm ProNest and ProNest LT software is supplied by Hypertherm and is not included in any of the training sessions described below. Find more information at the Hypertherm Knowledge Base (https://www.hypertherm.com/en-US/support/software/knowledge-base/) or contact your Piranha sales representative for assistance.

Piranha Factory Group Training

Piranha Factory Group Training at the Piranha facility in Rockford, IL, is available to supplement the information provided with your Piranha plasma machine. Joining other Piranha plasma cutting table users, you will be trained by an experienced Piranha applications engineer on a system as close as possible to your machine configuration. Class size is limited to available openings at the time of enrollment. Contact Piranha for availability.

Piranha Factory Private Training

Piranha Factory Private Training at the Piranha facility in Rockford, IL, is available to supplement the Piranha instructional videos. Working specifically with your parts and drawings, you will be trained on a system as close as possible to your machine configuration. A maximum of three (3) of your team members will be hosted and trained by an experienced Piranha applications engineer.

Customer Location Training

A Piranha application engineer is available to assist with training at your location based on our standard application engineering rates. A one-day training session (maximum of 3 of your team members) will include travel time, expenses, and one day of machine training. Multiple day sessions are available if needed. Contact your Piranha sales representative for a quote based on your location. The machine must be operational before the training starts. Contact Piranha service for assistance as needed.

| |

PIRANHA FACTORY GROUP TRAINING |

PIRANHA FACTORY PRIVATE TRAINING |

CUSTOMER LOCATION TRAINING |

| Self-Installation “How To” |

X |

X |

X |

| Start-up |

X |

X |

X |

| Basic Plasma Cutting |

X |

X |

X |

| Control Operation |

X |

X |

X |

| Shape Library |

X |

X |

X |

| Plasma Processes |

X |

X |

X |

| Plasma Consumables |

X |

X |

X |

| Plasma Parameters Set-up |

X |

X |

X |

| Hands-On Operation |

X |

X |

X |

| Hands-On Basic Maintenance |

X |

X |

X |

| Programming and Running Typical Parts |

X |

X |

X |

| Programming and Running Your Specific Parts |

|

X |

X |

UTILITY REQUIREMENTS

Required:

- 120V SINGLE PHASE AC / 20A service for table and CNC control.

NOTE: A transformer will be required if other voltages, such as 208V, are supplied.

Connection of other voltages to the machine will void the warranty unless approved in writing by Piranha.

- Separate Electrical Service for Hypertherm Plasma System. The Hypertherm Powermax series is available with several power options. Consult factory for information.

- Dry Compressed air – 90 psi minimum

- Earth Ground Rod with separate green insulated number 4 stranded copper welding cable leading to plasma cutting system

Recommended:

- Air Dryer Unit or Three-Stage Filter System

ASSEMBLY / INSTALLATION

Customer is responsible for the complete assembly and installation of the equipment including (but not limited to):

- The a series requires complete assembly. Estimated one person eight hours.

- Rigging

- Leveling

- Electrical Installation

- Start-up

Piranha will supply appropriate installation and operations manuals for performing installation. Installation and training by Piranha field service technicians is available at prevailing rates. Technical support for installation and ongoing operation is available via phone at no charge.

If customer purchases plasma system from another source, then customer will be responsible for the connection and integration of the plasma system to the machine.

WARRANTY

Twelve (12) month parts warranty, covering defects in materials or workmanship.

DELIVERY

Normal delivery is from stock subject to confirmation at the time of order. Price is FOB factory Rockford, Illinois and does not include any applicable sales tax or installation. The machine is shipped totally wired through to the electrical enclosure box. It has been left to the purchaser’s discretion whether to wire direct to a disconnect or to install a cord and plug for mobility.

SHIPMENT REQUIREMENTS

Piranha requires Flatbed Trailer(s), with adequate chains and tarps (to cover full height and width), to assure protection of this equipment when using truck transportation. Please make sure that adequate deck space is allotted for the machine and all accessories shipping with order. Upon request, Piranha will arrange shipping to destination. Freight and insurance charges are the responsibility of the customer and will be invoiced on machine order. Please consult the factory for any questions regarding shipping requirements.

PAYMENT TERMS

Stock machines require 100% payment prior to shipment. Non-stock machines require a down payment of 50%, with the remaining 50% due prior to shipment.

*Prices and specs subject to change without notice.