Piranha FLEX LASER cutting machines are built with reliability and economy in mind. These tough machines use proven technology to ensure precision and reliability throughout their service life. This special combination of durability and cost efficiency provides maximum value for steel processors.

Your Piranha FLEX LASER can be configured with a range of resonators, cutting heads, dust collectors, and performance options to balance your LASER cutting requirements with your budget.

Piranha Flex LASER Models include:

- Flex 510 (5’x10′)

- Flex 512 (5’x12′)

- Flex 520 (5’x20′)

- Flex 613 (6’x13′)

- Flex 620 (6’x20′)

- Flex 820 (8’x20′)

SYSTEM FEATURES

- Cutting envelopes from 5’x 10’ to 8’ x 20’

- Solid-state fiber power supply resonators from 3kW to 20kW with an auto-focus cutting head appropriate for the selected power level

- Chiller

- Helical rack and pinion positioning system with automatic lubrication

- 3,150 IPM (80 m/min) or 3,937 (100 m/min) maximum travel rate per axis

- Cypcut or Hypcut graphic CNC control

- Red diode LASER pointer

- Automatic Cutting Gas Control and proportional valve

- Nozzle cleaner

- ProNEST® LT UNLIMITED programming software

CUTTING TABLE WITH FUME EXTRACTION SYSTEM AND DUST COLLECTOR

- Automatic Shuttle Table with Two (2) Pallets

- Integrated multiple zone fume extraction system with replaceable heat shields

- Available dust collectors with solutions for steel and aluminum cutting

PIRANHA SERVICE AND SUPPORT – ROCKFORD, IL

- Spare parts available from the Piranha multi-million-dollar inventory

- Operator, maintenance, and application training at the factory, online with live host, and during installation

- Control software support by Piranha

- Technical service by remote diagnostics, phone, email, and onsite by highly trained and experienced Piranha service engineers

LASER POWER SOURCE

Piranha FLEX LASERs can be equipped with a variety of LASER powers and resonators. Each brand and configuration has benefits. Consult with your Piranha dealer or sales representative for more information.

Note: Other power levels and configurations are available as special orders.

FLEX STANDARD LASER CONFIGURATIONS

3.0kW

- VALUE Fiber Resonators & Piranha Cutting Head

- IPG YLR rack mount & LaserMech Cutting Head

- IPG YLS stand-alone & LaserMech Cutting Head

- nLIGHT & LaserMech Cutting Head

- nLIGHT Corona & LaserMech Cutting Head

6.0kW

- VALUE Fiber Resonators & Piranha Cutting Head

- IPG YLR rack mount & LaserMech Cutting Head

- IPG YLS stand-alone & LaserMech Cutting Head

- nLIGHT & LaserMech Cutting Head

- nLIGHT Corona & LaserMech Cutting Head

12.0kW

- VALUE Fiber Resonators & Piranha Cutting Head

- IPG YLS stand-alone & LaserMech Cutting Head

- nLIGHT & LaserMech Cutting Head

- nLIGHT Corona & LaserMech Cutting Head

20.0kW

- VALUE Fiber Resonators & Piranha Cutting Head

MAX PHOTONICS

MAX Photonics opened in 2004 with its international headquarters in Shenzhen, China. More information is available at MAX Photonics.

RAYCUS

Raycus was established in 2007 and is headquartered in Wuhan, Ching. In March 2013, it developed China’s first 10kW industry-level fiber LASER, making China the second country to master the core technologies of 10,000W fiber LASER in the world. More information can be found at Raycus.

IPG

IPG Photonics was founded in 1991. In 2000, IPG invested in new high-capacity production facilities in the United States to manufacture its own LASER diode pumps, a major component of its fiber LASERs and amplifiers. More information can be found at IPG Photonics.

nLIGHT

nLIGHT was founded in 2000 in Vancouver, WS to focus on high-power semi-conductor LASERs. More information can be found at nLIGHT.

nLIGHT CORONA

nLIGHT Corona fiber LASERs give users the ability to tune the beam settings based on their application. With a single fiber LASER, users can rapidly select from high-intensity, small-spot-size beams to large, donut-shaped beams, and everything in between. This dramatic advance allows optimal thick and thin metal cutting, higher cutting speed, superior quality, and improved piercing and small-feature processing with a single tool. End users get the best of all worlds—the speed of high-power fiber LASERs for thin metal processing, the quality of CO2 LASERs for thick metal processing, and the high uptime and lower operating costs of a fiber LASER solution.

- 3kW to 15kW – Deliver excellent productivity for advanced cutting and welding applications.

- Optimized Tuning of Beam Size and Shape – Maintains fiber LASER performance, stability, efficiency, and reliability with spot sizes from 100µm to 300µm and beam shapes from top-hat to donut mode.

- Rapid Beam Switching – Beam adjustments in less than 30ms allows for real-time optimization of each process step while maintaining full power operation to maximize productivity.

- Back-Reflection Protection – Hardware-based back-reflection protection allows processing of even the most reflective metals with no interruptions or damage to the LASER.

- Breakthrough Integrated Beam Shaping – Removal of free-space optics, zoom process heads, and external fiber-to-fiber couplers avoids complex performance-limiting hardware.

- Unparalleled Serviceability – Modular design simplifies repairs and maximizes uptime.

CUTTING HEADS

Piranha FLEX LASERs integrate different cutting head designs which are matched to the requirements and performance of the selected resonator make and power.

Piranha cutting heads are implemented in collaboration with our manufacturing partners in China. LaserMech cutting heads are provided from their facility in Michigan.

| |

|

CUTTING HEAD |

|

| RESONAT0OR POWER AND SOURCE |

Piranha |

LaserMech® FiberMINI® |

LaserMech® FiberCUT 2D |

LaserMech® FiberCUT 2Dx |

| 3kW VALUE |

X |

|

|

|

| 6kW VALUE |

X |

|

|

|

| 12kW VALUE |

X |

|

|

|

| 20kW VALUE |

X |

|

|

|

| 3kW IPG or nLIGHT |

|

X |

|

|

| 6kW IPG or nLIGHT |

|

|

X |

|

| 12kW IPG or nLIGHT |

|

|

|

X |

| 20kW IPG or nLIGHT |

|

|

|

X |

Piranha

Piranha auto-focus cutting heads are designed for cutting applications using from 3kW to 20kW power. Heads may include features such as high speed focusing, modularized cover glass holders, optics temperature monitoring, water cooling.

LaserMech™

LaserMech FiberMINI®

FiberMINI® is a simple and flexible design in a compact, lightweight cutting head. The head can cut a wide range of materials delivering user-friendly operation and reliable performance.

- Temperature sensors protect optics and minimize the chance of overheating

- 13 mm of lens movement to set focus

- Quick, toolless access to the sealed cover glass

- Nozzle cooling for use with highly reflective materials

- Sealed optics

LaserMech FiberMINI™ AF

FiberMINI® AutoFocus (AF) is a compact, lightweight design optimized for flat sheet fiber LASER cutting. The head can process a wide range of materials with automatic, programmable focus. and delivers both user-friendly operation and reliable performance.

- 14 mm of programmable autofocus to set focus position

- Temperature sensors protect optics and minimize the chance of overheating

- Quick, toolless access to the sealed cover glass

- End-user serviceable focus lens

- Nozzle cooling for use with highly reflective materials

- Sealed optics LaserMech FiberCUT® 2D

LaserMech FiberCUT™ 2D

FiberCUT® 2D cutting heads deliver cutting-edge performance for flatbed systems up to 8 kW. Featuring automatic, programmable focus with 25 mm of travel, FiberCUT® 2D is a fully sealed, purged design that minimizes the chance of internal contamination. Ther are two cover glasses; one below the focus lens and a second below the fiber to protect collimator optics. Sealed access doors prevent contamination when cover glasses are serviced.

- 25 mm of programmable autofocus to set focus position

- Internal sensors to determine the condition of all optics

- Standard nozzle cooling and air blast

LaserMech FiberCut® 2Dx

FiberCUT® 2Dx cutting heads deliver the largest diameter optics and clear aperture for high-power LASER cutting. Featuring LaserMech’s new autofocus system, FiberCUT® 2Dx is 3-5 times faster than the original FiberCUT® 2D. Internal sensors monitor humidity, and both internal and assist gas pressure. Improved water cooling provides reliable, continuous cutting up to 20 kW.

- Internal sensors determine the condition of all optics

- Fully sealed, end-user, service-friendly optics

- Internal process monitoring detects pierce-through and loss of cut

- Standard nozzle cooling and optional air blast

CNC CONTROLS

Cypcut 4000 CNC

Piranha FLEX-series LASERs include a graphical CNC control with Cypcut software. It is a control system and software designed for sheet metal fabrication. Individual or multiple parts are imported as DXF files and can be nested automatically or manually. No knowledge of G- and M-codes is required.

Cypcut software is available as a free download and can be installed on any number of computers for offline programming at no additional cost. The completed nests can be directly transferred to the LASER CNC control via a network connection.

Features include:

- AI, DXF, PLT, Gerber, LXD file format, and standard G code import

- File optimization including removal of duplicates, connecting unclosed segments, removing minimal graphics and distinguishing inner and outer contour and setting machining sequence automatically.

- Graphic edit functions including zooming, translation, mirror, rotation, alignment, replication, and combination.

- Application of lead lines, cut seam compensation, micro-joint, bridge, inner/outer cut, etc.

- Automatically distinguish inner and outer contour then determine the compensation direction and checking of the lead line.

- Support curve split, merge and smooth; transfer text to curve; parts combination and explode etc.

- Automatic nesting including common line cutting and remnant nesting.

- Manual nesting by array function.

- Flexible sorting functions. Users can group the graphics to lock the cutting sequence.

- Preview the cutting sequence.

- Quick set fly cutting.

- Support of various piercing methods including segmented pierce, incremental pierce, pre-pierce, group pre-pierce. Users can also set separate parameters of pierce and cutting including LASER power, frequency, gas, pressure, peak power, delay, cut height etc.

- Powerful material library function allows all process parameters to be saved for reuse of the same material.

- Breakpoint memory when the cutting process is interrupted. Users can select resume position before or after breakpoint.

- Users can locate to specified position in stop or pause status and resume cutting.

- Supports round tube and plane sheet cutting.

- Supports intersecting line cutting.

- Supports various edge-find methods with high precision.

- Supports remote control of the system through wireless operator and ethernet.

Service, training, and support of the CNC control and Cypcut is provided by Piranha.

Hypcut 8000 CNC

Piranha FLEX-series LASERs offer the graphical Hypcut 8000 CNC control. Offering the same features as the Cypcut 4000 CNC, the Hypcut 8000 CNC includes advanced features to support high power resonators.

Hypcut software is available as a free download and can be installed on any number of computers for offline programming at no additional cost. The completed nests can be directly transferred to the LASER CNC control via a network connection.

DUST COLLECTORS

TOPSINN DUST COLLECTOR

Topsinn dust collectors include an independent controller with LCD screen, Siemens motors, and pulse control backflush valves. The solid industrial design provides for easy low cost maintenance and stable, low noise operation.

CAMFIL DUST COLLECTOR

FARR GOLD SERIES® Packaged Dust Collector

- Built-in spark baffle inlet to protect cartridges

- Standard easy-to-remove dust drawer(s)

- Factory installed sprinkler head mounted in dust collector

CONSTRUCTION

- Gold Series module is constructed of 7 gauge steel

- Door, hopper, inlet and panels are all 10 gauge steel

- Powder Paint Finish

AUTOMATIC FILTER CLEANING

- Filters are automatically back-flush cleaned with periodic pulses of compressed air

- Vertical design of the Camfil APC cartridges provides more efficient pulsing of dust, thus eliminating uneven dust loading associated with horizontally mounted cartridges INTEGRATED CONTROLS

- Hand/off/auto switch for direct control of dust collector

- On-demand pulse cleaning controls

- Digital and analog readout of filter pressure differential, alarm output of high pressure

- Control voltage transformer FILTER ACCESS

- Tool-less quick-open access door(s)

- Cam-operated clamp bars INLET

- Standard collared inlet allows for quick and easy hose connection

- Perforated plate installed in the inlet protect the filters from incoming dust and separates the larger dust particles directly into the hopper, reducing the load on the filters

- Includes integral inlet damper for airflow control

ASSIST GAS CUTTING SYSTEMS

AIR ASSIST GAS CUTTING SYSTEMS

Oxygen (O2) and nitrogen (N2) are the most common assist gases used when cutting metals with a fiber LASER. Air is a combination of both O2 (21%) and N2 (78%), small amounts of argon and carbon dioxide, and trace amounts of other gases and water vapor.

Air cutting provides many of the benefits of N2 cutting along with increased cutting speeds in thicknesses 10ga (0.135”) and thinner and significantly lower cutting gas costs.

Air used in LASER cutting must be available with the correct purity, dryness, pressure, and flow. Typical shop air compressor systems are unable to deliver the air quality and performance necessary. A dedicated air compressor system is required.

|

F30 (SUPPORTS ONE MACHINE) |

| Air Flow Rate |

1,800 SCFH |

| Delivery Pressure |

204 PSIG |

| Air Compressor |

20 HP |

| Components |

- Fixed speed rotary screw air compressor

- Compressed air tank

- Compressed air filtration assembly

- Membrane dryer

|

|

F50 (SUPPORTS TWO MACHINES) |

| Air Flow Rate |

3,000 SCFH |

| Delivery Pressure |

204 PSIG |

| Air Compressor |

25 HP Ozen Compressor |

| Components |

- Fixed speed rotary screw air compressor

- Compressed air tank

- Compressed air filtration assembly

- Membrane dryer

|

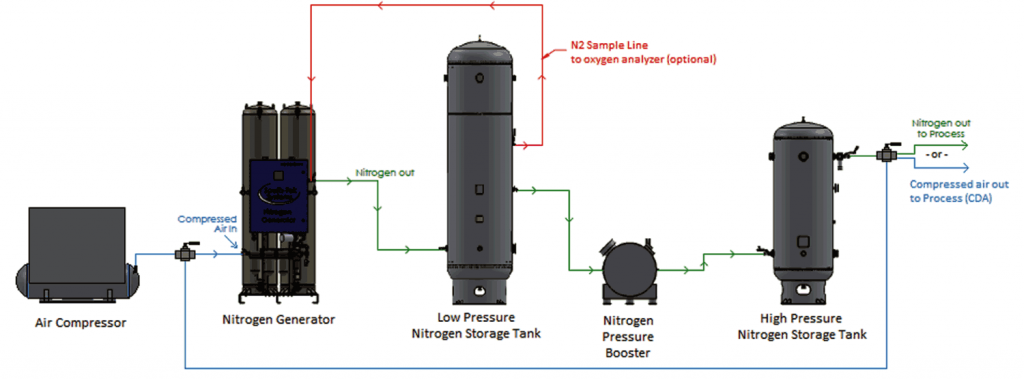

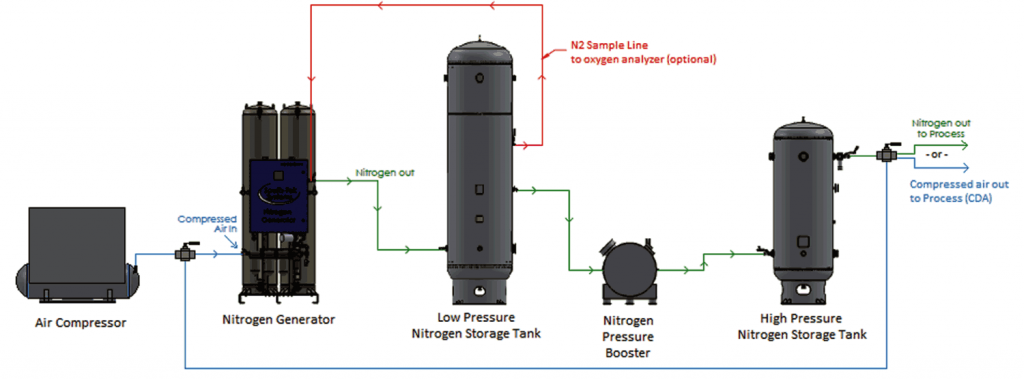

NITROGEN GENERATION SYSTEMS

Nitrogen generator is the separation of air components to capture nitrogen. Nitrogen makes up 78% of the gas in the atmosphere. The rest is 20.9% oxygen, 0.9% argon, 0.03% carbon dioxide and trace gases such as hydrogen, helium, neon, krypton, and xenon. For industrial LASER cutting equipment, PRESSURE SWING ABSORPTION (PSA) is used to provide the high pressures and flow rates required.

NOTE: The maximum flow rate and purity required depend upon the cutting application and edge quality expectations. Other nitrogen generation systems are available to meet different requirements. Please contact Piranha for more information.

|

F3000 |

F4000 |

F5000 |

| N2 Flow Rate |

3,000 SCFH |

4,000 SCFH |

5,000 SCFH |

| Purity |

99.50% |

99.50% |

99.50% |

| Delivery Pressure |

400 PSIG |

400 PSIG |

400 PSIG |

| Air Compressor |

40 HP |

50 HP |

60 HP |

| Booster Compressor |

10 HP |

20 HP |

20 HP |

| Warranty |

3 years |

| Components |

- Fixed speed rotary screw air compressor

- Refrigerated air dryer

- Condensate oil / water separator

- Compress air tank

- Oil mist eliminator

- Compressed air filtration assembly

- Nitrogen generator with touch screen display

- Nitrogen buffer tank

- Booster compressor

- High pressure tank

- Four stage high pressure filtration assembly

|

MACHINE OPTIONS

CONSUMABLE KITS

Consumable kits are available which provide a starting stock of items that are recommended for a range of LASER cutting applications. If a different combination of items is desired, please contact the sales department for a quotation specific to those items.

REMOTE CNC CONTROL STATION

The Remote CNC Control Station is located at the rear of the LASER enclosure and includes dual monitors and a keyboard. The main CNC control screen and video feed is mirrored. This system allows for LASER operation when loading or unloading the pallets.

POP-UP BALL TRANSFER SHEET LOADING ASSIST SYSTEM

The pop-up ball transfer sheet loading assist system is designed to allow material to be easily moved to the material reference stops. Ball transfers will raise to a location above the pallet slats. Once the operator locates the work piece against the stops, the ball transfers will retract so that the work piece rests directly on the slats, in the correct zero location. The system is located below the outside pallet and will work with either pallet in the pallet load location. This system is available for 510 and 613 configurations. Consult with your Piranha sales representative if another size is requested.

LAMINAR FLOW BOX

Piranha recommends preparing an optics servicing area located away from manufacturing area. This area must have minimum air movement and a dust free environment. For best results, we recommend purchase of a laminar flow box located in an office area.

NOTE: Optics contamination is the leading cause of premature cutting head failure. It is important that optics, such as cover slides, are changed in an extremely clean environment. This area will also be used for on-site cutting head maintenance (to be done by our technicians).

CAM PROGRAMMING AND NESTING SOFTWARE

CNC Programming of the Piranha FLEX requires CAM software capable of supporting the advanced functions of the machine. The customer is responsible for all costs associated with the development of any new post processor from their selected CAM software vendor. Piranha will provide any information required for the post processor development and will verify that the NC code samples created by that post processor are functional. Requests for information and NC code samples for testing must be

received by Piranha eight (8) weeks prior to the scheduled machine shipment.

If extra start-up time is required by Piranha to work with the CAM provider and to test the NC code during or after the machine installation, the additional Piranha service time and expenses will be invoiced to the customer at Piranha’s standard service rates

FACILIITY REQUIREMENTS

AMBIENT CONDITIONS

The Piranha FLEX must be in an area which has the following ambient conditions:

- Ambient temperature between 10° and 40°C [50° and 104°F]

- Relative Humidity at 95% or less

NOTE: Piranha requires that the LASER and chiller always remain on to avoid costly damage from condensation.

FOUNDATION REQUIREMENTS

No special foundation is needed for the Piranha FLEX LASER. Standard concrete floors of a minimum 150mm (6”) depth are recommended. Flatness should be within 12mm (0.5”). There should be no expansion joints, saw cuts, or cracks in the floor beneath the frame of the LASER.

ELECTRICAL POWER

| ITEM |

VOLTAGE |

CURRENT |

| Machine and LASER Resonator 3kW-6kW |

480/3/60 VAC (WYE TYPE) |

75A |

| Machine and LASER Resonator 12kW |

|

|

| Machine and LASER Resonator 20kW |

|

|

| Dust Collector |

480/3/60 VAC |

15A |

NOTE: Transformers are available for other voltages. Contact Piranha for more information.

CUTTING GAS

| GAS |

PURITY |

CONSUMPTION |

| Oxygen

(Mild Steel Cutting) |

99.95% |

40 ~ 350 SCFH @ 140 PSI

19 ~ 165 L/min @ 9.5 Bar |

| Nitrogen

(Stainless, Aluminum Cutting) |

99.8% |

320 ~ 3000 SCFH @ 300 PSI 150 ~ 1,400 L/min@ 20 Bar |

NOTE: Customer shall install and utilize bulk liquid oxygen and bulk liquid nitrogen storage tanks. Using portable tanks for O2 or N2 will create additional chances of contamination entering the gas supply lines and the cutting head due to frequent tank changes. Cont0.amination will cause cutting head lens failure and thus cause machine down time and additional operating expense.

BUDGETARY PROPOSAL

This budgetary proposal is a reference document and subject to change without notice. Upon request, a final proposal will be issued including firm pricing and contractual information. This budgetary proposal is not an agreement on pricing or specifications.